-

HTD Taper Bore Timing Pulleys

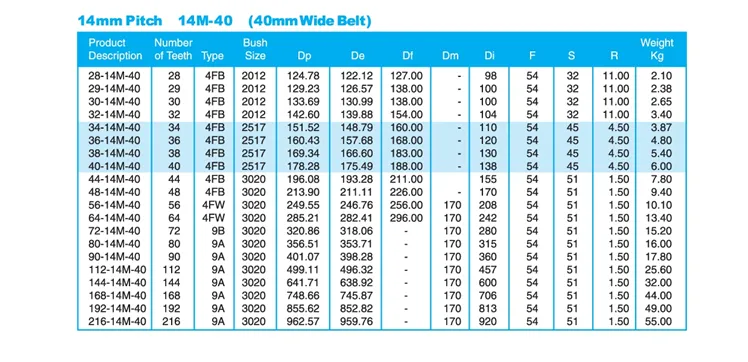

14mm Pitch 14M-40(40mm Wide Belt) 14mm Pitch 14M-55(55mm Wide Belt)

14mm Pitch 14M-85(85mm Wide Belt) 14mm Pitch 14M-115(115mm Wide Belt)

14mm Pitch 14M-170(170mm Wide Belt)

Material: Steel, Cast Iron

We can supply different size timing belt pulleys.

HTD 14M-40 pulley for belt width 40 mm

28-14M-40, 30-14M-40, 32-14M-40, 34-14M-40, 36-14M-40, 38-14M-40,

40-14M-40, 44-14M-40, 48-14M-40, 56-14M-40, 64-14M-40, 72-14M-40,

80-14M-40, 90-14M-40, 112-14M-40, 144-14M-40, 168-14M-40, 192-14M-40

HTD 14M-55 pulley for belt width 55 mm

28-14M-55, 30-14M-55, 32-14M-55, 34-14M-55, 36-14M-55, 38-14M-55,

40-14M-55, 44-14M-55, 48-14M-55, 56-14M-55, 64-14M-55, 72-14M-55,

80-14M-55, 90-14M-55, 112-14M-55, 144-14M-55, 168-14M-55, 192-14M-55

HTD 14M-85 pulley for belt width 85 mm

28-14M-85, 30-14M-85, 32-14M-85, 34-14M-85, 36-14M-85, 38-14M-85,

40-14M-85, 44-14M-85, 48-14M-85, 56-14M-85, 64-14M-85, 72-14M-85,

80-14M-85, 90-14M-85, 112-14M-85, 144-14M-85, 168-14M-85, 192-14M-85

-

The timing pulley is the mechanical part used to transmit power between the crankshaft and camshaft of the engine.

It is usually made of aluminum or steel and contains teeth that mesh with the timing belt to ensure proper synchronization between the two shafts.

The pulley is mounted on the end of the camshaft and is responsible for driving the timing belt which in turn drives the camshaft.

This allows the valves in the engine to open and close at the appropriate times, ensuring optimum engine performance.

Timing pulleys are found in a variety of engines, including those found in cars, trucks, and industrial equipment.

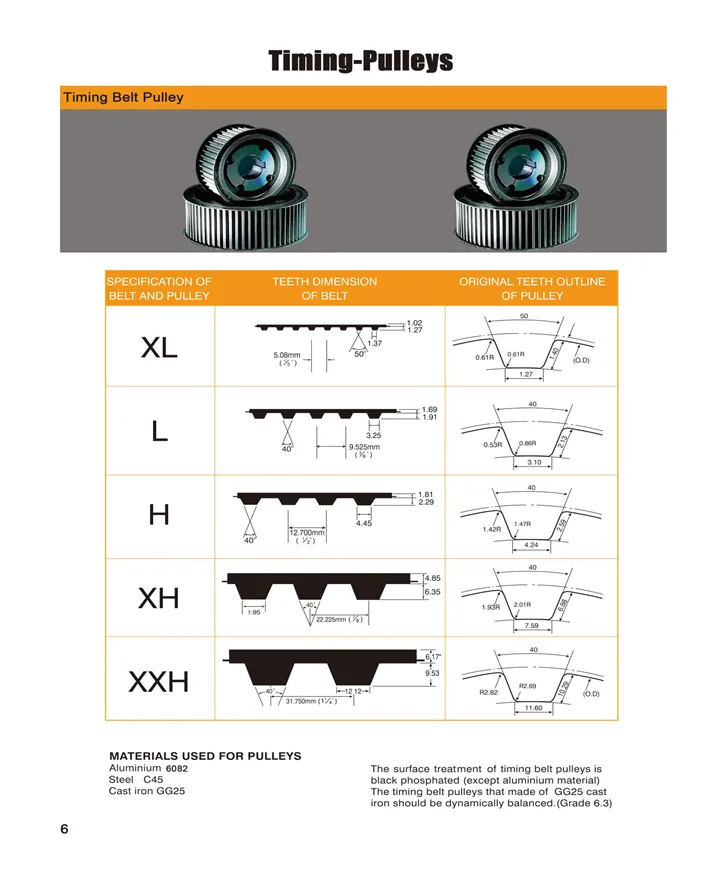

Materials used for timing pulleys Alumimium 6082 Steel C45 Cast iron GG25

The surface treatment of timing belt pulleys is black phosphate (except aluminum material).The timing belt pulleys that made of GG25 cast iron should be dynamically balanced. (Grade 6.3)

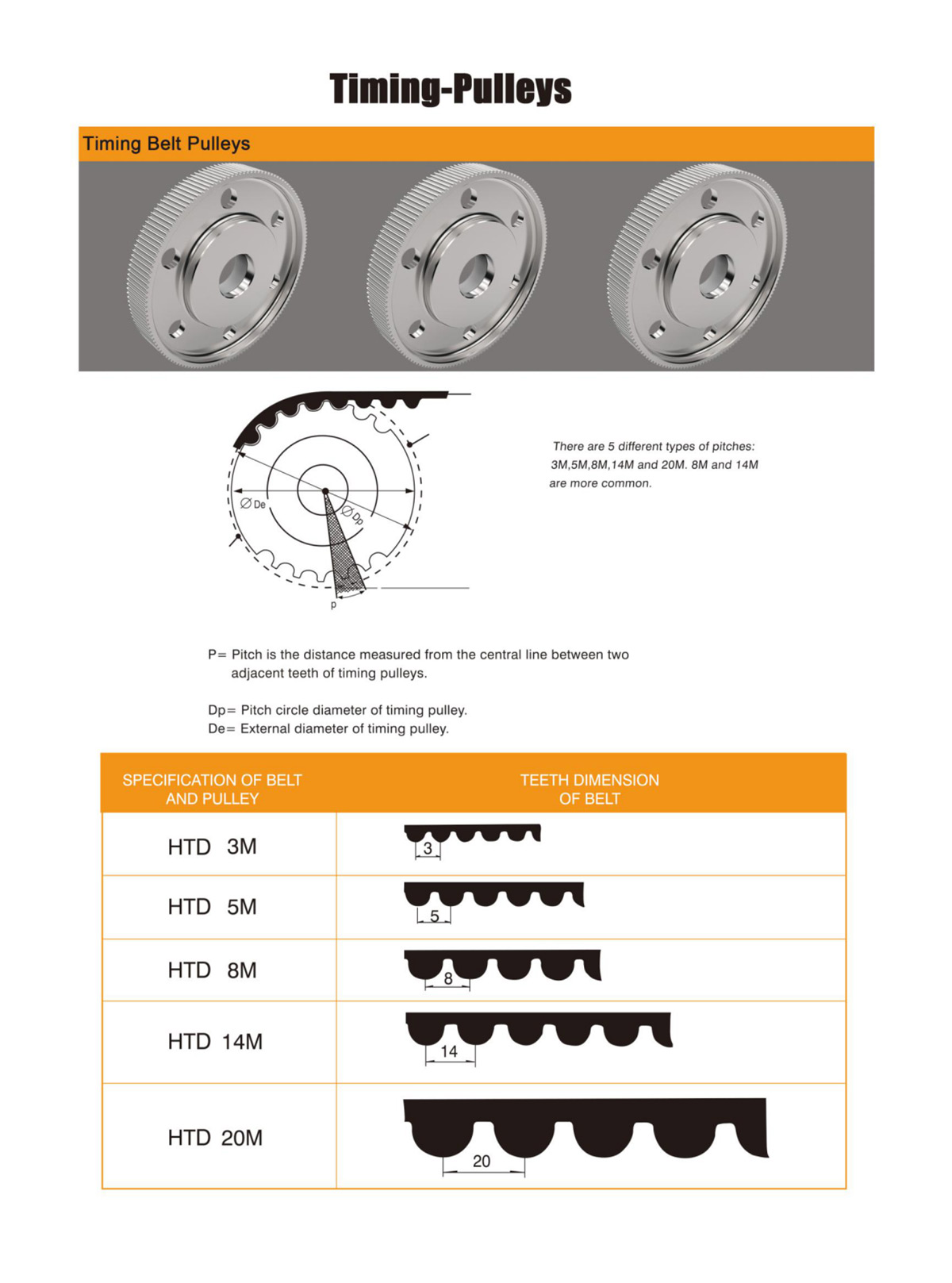

Product Name Aluminum Timing Pulley XL L H XH XXH T2.5 T5 T10 AT5 AT10 GT2 GT3 GT5 3M 5M 8M

Tooth timing Belt PulleyTeeth profile Trapezoidal toothed XL, L, H, XH, XXHT-toothed T2.5, T5, T10, T20

Arc toothed HTD3M, HTD5M, HTD8M, HTD14M, HTD20M, Gt2, Gt3, Gt5

Teeth Quantity 10-150 teeth or customized

Inner Bore 2-200mm H7 precision or customized

Belt width 4mm, 6mm, 9mm, 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 1/4”, 5/16”, 3/8”, 1/2”, 3/4”, 1”, 1.5”, 2”or customized

Material cast iron GG25 , steel C45, Aluminum 6061, 6082

Surface treatment Anodize, Black Oxide, Phosphate, Galvanization

-

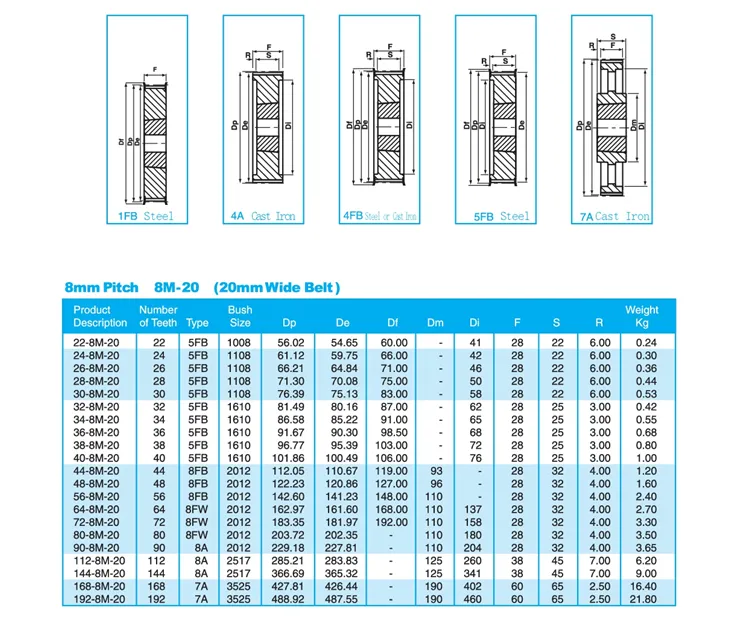

HTD Taper Bore Timing Pulleys 8mm Pitch 8M-20(20mm Wide Belt) 8mm Pitch 8M-30(30mm Wide Belt)

8mm Pitch 8M-50(50mm Wide Belt) 8mm Pitch 8M-85(85mm Wide Belt)

Material: Steel, Cast Iron

We can supply different size timing belt pulleys.

HTD 8M-20 pulley for belt width 20 mm

P22-8M-20, P24-8M-20, P26-8M-20, P28-8M-20, P30-8M-20, P32-8M-20,

P24-8M-20, P36-8M-20, P38-8M-20, P40-8M-20, P44-8M-20, P48-8M-20,

P56-8M-20, P64-8M-20, P72-8M-20, P80-8M-20,P 90-8M-20

HTD 8M-30 pulley for belt width 30 mm

P22-8M-30, P24-8M-30, P26-8M-30, P28-8M-30, P30-8M-30, P32-8M-30,

P34-8M-30, P36-8M-30, P38-8M-30, P40-8M-30, P44-8M-30, P48-8M-30,

P56-8M-30, P64-8M-30, P72-8M-30, P80-8M-30, P90-8M-30, P112-8M-30

HTD 8M-50 pulley for belt width 50 mm

P22-8M-50, P24-8M-50, P26-8M-50, P28-8M-50, P30-8M-50, P32-8M-50,

P34-8M-50, P36-8M-50, P38-8M-50, P40-8M-50, P44-8M-50, P48-8M-50,

P56-8M-50, P64-8M-50, P72-8M-50, P80-8M-50, P90-8M-50, P112-8M-50

HTD 8M-85 pulley for belt width 85 mm

P22-8M-85,P 24-8M-85, P26-8M-85, P28-8M-85, P30-8M-85, P32-8M-85

P34-8M-85, P36-8M-85, P38-8M-85, P40-8M-85, P44-8M-85, P48-8M-85

P56-8M-85,P 64-8M-85, P72-8M-85, P80-8M-85, P90-8M-85, P112-8M-85

-

-

-

-

-

-

-

-

-

V-belt pulleys is a pulley that has V-shaped grooves or channels around its circumference. It is used in machines or equipment that require power to be transmitted through a belt. The V-shape of the grooves helps prevent slippage and improves traction between the belt and pulleys, ensuring efficient power transfer. V-belt pulleys are commonly used in automotive engines, industrial machinery, agricultural equipment, and other types of heavy-duty applications.

V-belt pulleys (also called v- belt sheaves) are devices which transmit power between axles by the use of a v-belt, a mechanical linkage with a trapezoidal cross-section. Together these devices offer a high-speed power transmission solution that is resistant to slipping and misalignment.

V-belt pulleys are solely used for transmitting power between two parallel axels. The most notable difference between a v-belt pulley and other types of pulleys (round belt, flat, etc.) would be the geometry of the groove or grooves located around the circumference of the pulley; these grooves guide and gain traction on a v-belt.

A v-belt is a unique mechanical linkage with a cross-section that resembles an isosceles trapezoid. The v-belt and its complementing pulley create the most efficient belt drive known (sometimes achieving 98% transmission efficiency). V-belts were developed in the early days of automobile innovation to improve belt reliability and torque transmission from the crankshaft to rotating assemblies. V-belts remain a common type of serpentine belt today.

V-belt transmissions are a notable upgrade from round or flat belt transmissions; v-belts provide excellent traction, speed, and load capabilities, while enjoying an extended service life with simple replacement. Heavy loads actually increase transmission efficiency since they wedge the belt further into the pulley’s groove, thereby improving friction. Typically, v-belt drives operate between 1,500 to 6,000 ft/min, with 4,500 ft/min the ideal capacity for standard belts. Some narrow v-belts can operate at speeds of up to 10,000 ft/min, but these pulleys must be dynamically stabilized. V-belt pulleys may be placed in a side-by-side configuration or a single pulley may feature multiple grooves around the circumference in order to accommodate a multiple-belt drive. This type of drive distributes torque across several belts and provides a mechanical redundancy.

V belt pulley specifications:

1) European standard:

A) V-belt pulleys for taper bushings: SPZ, SPA, SPB, SPC; Up to 10 grooves

B) Adjustable speed V-belt pulleys and variable speed pulleys

C) Flat belt pulleys and conveyor belt pulleys

2) American standard:

A) Sheaves for taper bushings: 3V, 5V, 8V

B) Sheaves for QD bushings: 3V, 5V, 8V

C) Sheaves for split taper bushings: 3V, 5V, 8V

D) Sheaves for 3L, 4L or A, and 5L or B belts: AK, AKH, 2AK, 2AKH, BK, BKH, 2BK, 2BKH, 3BK

E) Adjustable sheaves: Poly V-pulley, multi-pitch H, L, J, K and M

3) Bore: Pilot bore, finished bore, taper bore, bore for QD bushing

4) Surface finish: Paint, phosphating, zinc plated

5) Material: Cast iron, ductile iron, nylon, aluminum

6) Made according to drawings and/or samples, OEM inquiries welcomedCast Iron V Belt Pulley,V pulley, v belt pulley, v groove pulley, v groove belt pulley, taper lock pulley, taper lock v belt pulley, taper lock bushing pulley, taper lock pulleys / taper bore pulley, large v belt pulley, double v belt pulley, cast iron v belt pulley belt pulley, variable speed v belt pulleys, v belt pulley split pulley, cast iron v belt pulley