-

Our company specializes in custom components for a variety of industries. We have the most advanced equipment and skilled technicians who can accurately process parts according to the drawings, models or physical samples you provide. We offer a wide range of machining services including CNC milling, turning, grinding, drilling and more. Our expertise and experience enable us to work with a wide variety of materials, from metals and alloys to plastics and composites. Whether you need one-offs or high-volume production, we can meet your needs. Our team is dedicated to satisfying your requirements through quality workmanship, prompt delivery and competitive prices. If you are looking for a reliable partner for your machining needs, please contact us today to discuss how we can serve you.

-

-

-

-

-

-

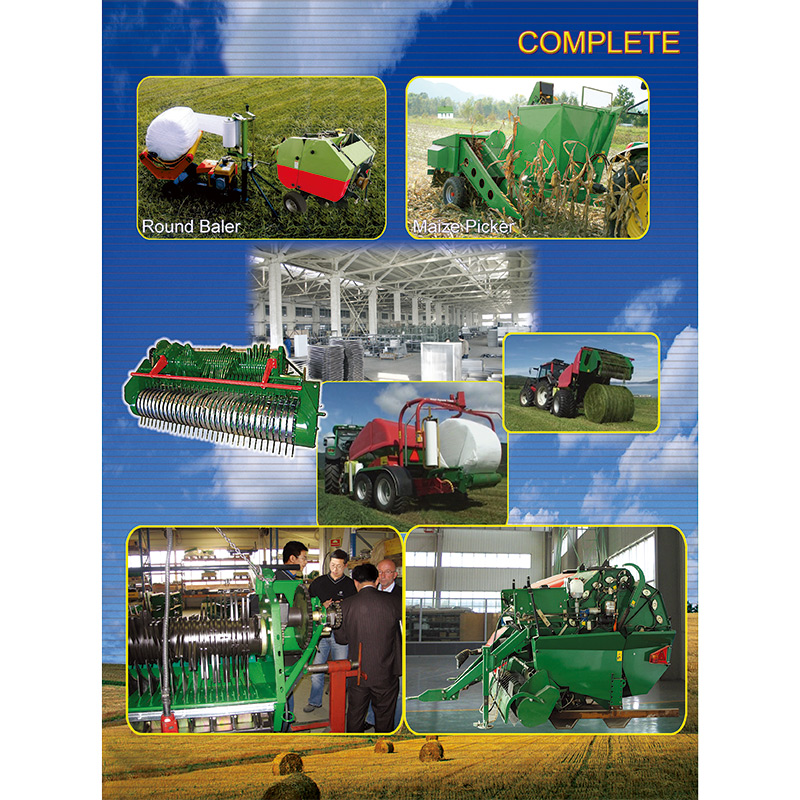

Our processing company focuses on providing customized processing of high-quality balers, mowers and other accessories for the agricultural machinery manufacturing industry.

Our many years of experience combined with a skilled technical team, modern equipment and high-quality materials make us a premium partner in this field.

We have always maintained a leading position in this industry. Professional technicians communicate directly with customers to provide customers with personalized processing solutions to ensure that each accessory can perfectly match the machine.

Our production line uses the latest CNC equipment, which can provide you with high-precision processing accessories, so that customers' machines can achieve more excellent operating results.

We can process not only various metals and alloy materials, but also plastics and composite materials.

Our customers are distributed all over the country, covering a very wide range, and we have a long-term cooperative relationship.

Our aim is to promise to provide customers with competitive prices and high quality products.

Our goal is to provide customers with better services through continuous innovation and improvement.

No matter you need any processing of agricultural machinery parts, we are willing to do our best to provide you with the highest quality, high efficiency and reliability.

-

V-belt pulleys is a pulley that has V-shaped grooves or channels around its circumference. It is used in machines or equipment that require power to be transmitted through a belt. The V-shape of the grooves helps prevent slippage and improves traction between the belt and pulleys, ensuring efficient power transfer. V-belt pulleys are commonly used in automotive engines, industrial machinery, agricultural equipment, and other types of heavy-duty applications.

V-belt pulleys (also called v- belt sheaves) are devices which transmit power between axles by the use of a v-belt, a mechanical linkage with a trapezoidal cross-section. Together these devices offer a high-speed power transmission solution that is resistant to slipping and misalignment.

V-belt pulleys are solely used for transmitting power between two parallel axels. The most notable difference between a v-belt pulley and other types of pulleys (round belt, flat, etc.) would be the geometry of the groove or grooves located around the circumference of the pulley; these grooves guide and gain traction on a v-belt.

A v-belt is a unique mechanical linkage with a cross-section that resembles an isosceles trapezoid. The v-belt and its complementing pulley create the most efficient belt drive known (sometimes achieving 98% transmission efficiency). V-belts were developed in the early days of automobile innovation to improve belt reliability and torque transmission from the crankshaft to rotating assemblies. V-belts remain a common type of serpentine belt today.

V-belt transmissions are a notable upgrade from round or flat belt transmissions; v-belts provide excellent traction, speed, and load capabilities, while enjoying an extended service life with simple replacement. Heavy loads actually increase transmission efficiency since they wedge the belt further into the pulley’s groove, thereby improving friction. Typically, v-belt drives operate between 1,500 to 6,000 ft/min, with 4,500 ft/min the ideal capacity for standard belts. Some narrow v-belts can operate at speeds of up to 10,000 ft/min, but these pulleys must be dynamically stabilized. V-belt pulleys may be placed in a side-by-side configuration or a single pulley may feature multiple grooves around the circumference in order to accommodate a multiple-belt drive. This type of drive distributes torque across several belts and provides a mechanical redundancy.

V belt pulley specifications:

1) European standard:

A) V-belt pulleys for taper bushings: SPZ, SPA, SPB, SPC; Up to 10 grooves

B) Adjustable speed V-belt pulleys and variable speed pulleys

C) Flat belt pulleys and conveyor belt pulleys

2) American standard:

A) Sheaves for taper bushings: 3V, 5V, 8V

B) Sheaves for QD bushings: 3V, 5V, 8V

C) Sheaves for split taper bushings: 3V, 5V, 8V

D) Sheaves for 3L, 4L or A, and 5L or B belts: AK, AKH, 2AK, 2AKH, BK, BKH, 2BK, 2BKH, 3BK

E) Adjustable sheaves: Poly V-pulley, multi-pitch H, L, J, K and M

3) Bore: Pilot bore, finished bore, taper bore, bore for QD bushing

4) Surface finish: Paint, phosphating, zinc plated

5) Material: Cast iron, ductile iron, nylon, aluminum

6) Made according to drawings and/or samples, OEM inquiries welcomedCast Iron V Belt Pulley,V pulley, v belt pulley, v groove pulley, v groove belt pulley, taper lock pulley, taper lock v belt pulley, taper lock bushing pulley, taper lock pulleys / taper bore pulley, large v belt pulley, double v belt pulley, cast iron v belt pulley belt pulley, variable speed v belt pulleys, v belt pulley split pulley, cast iron v belt pulley

-

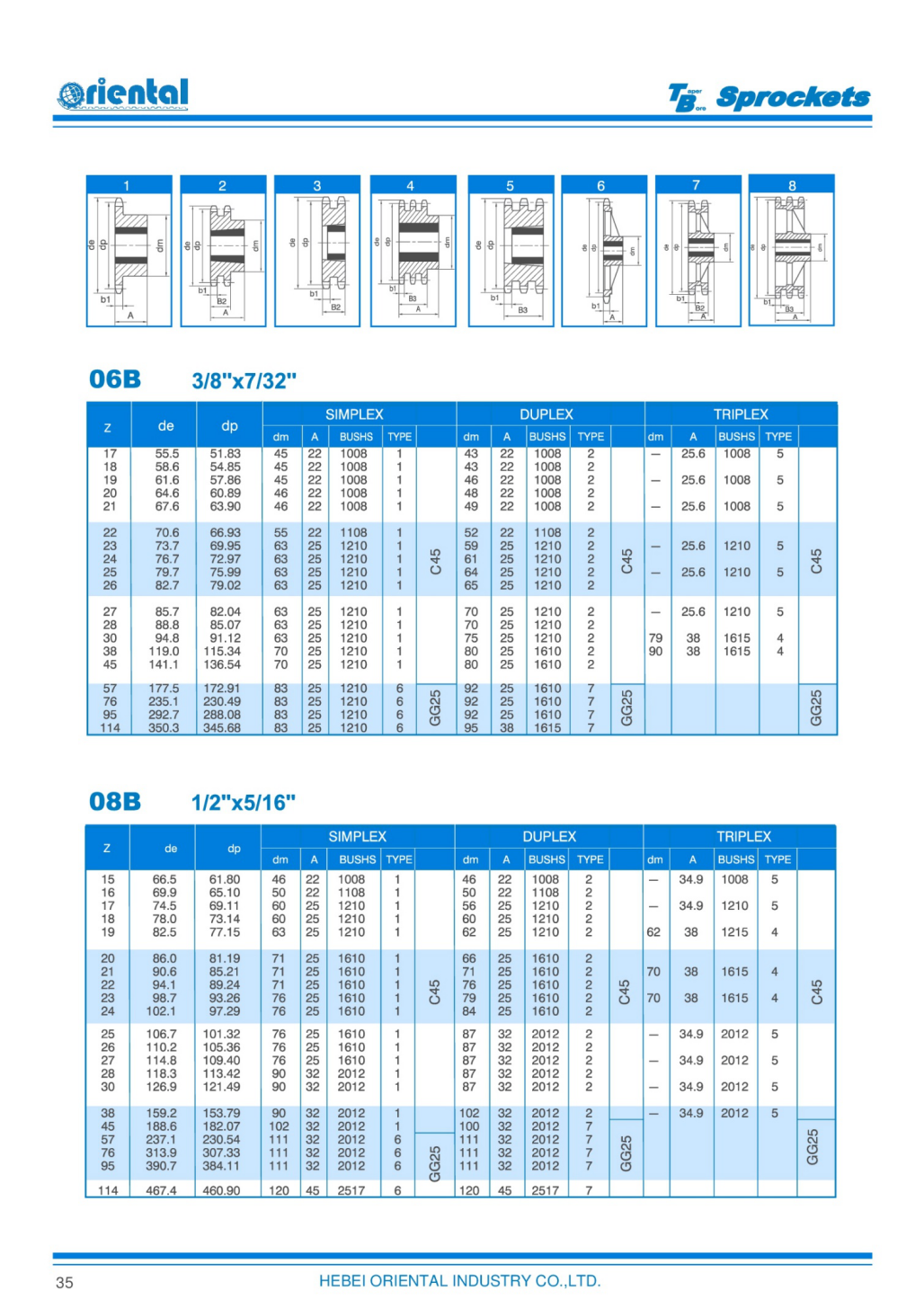

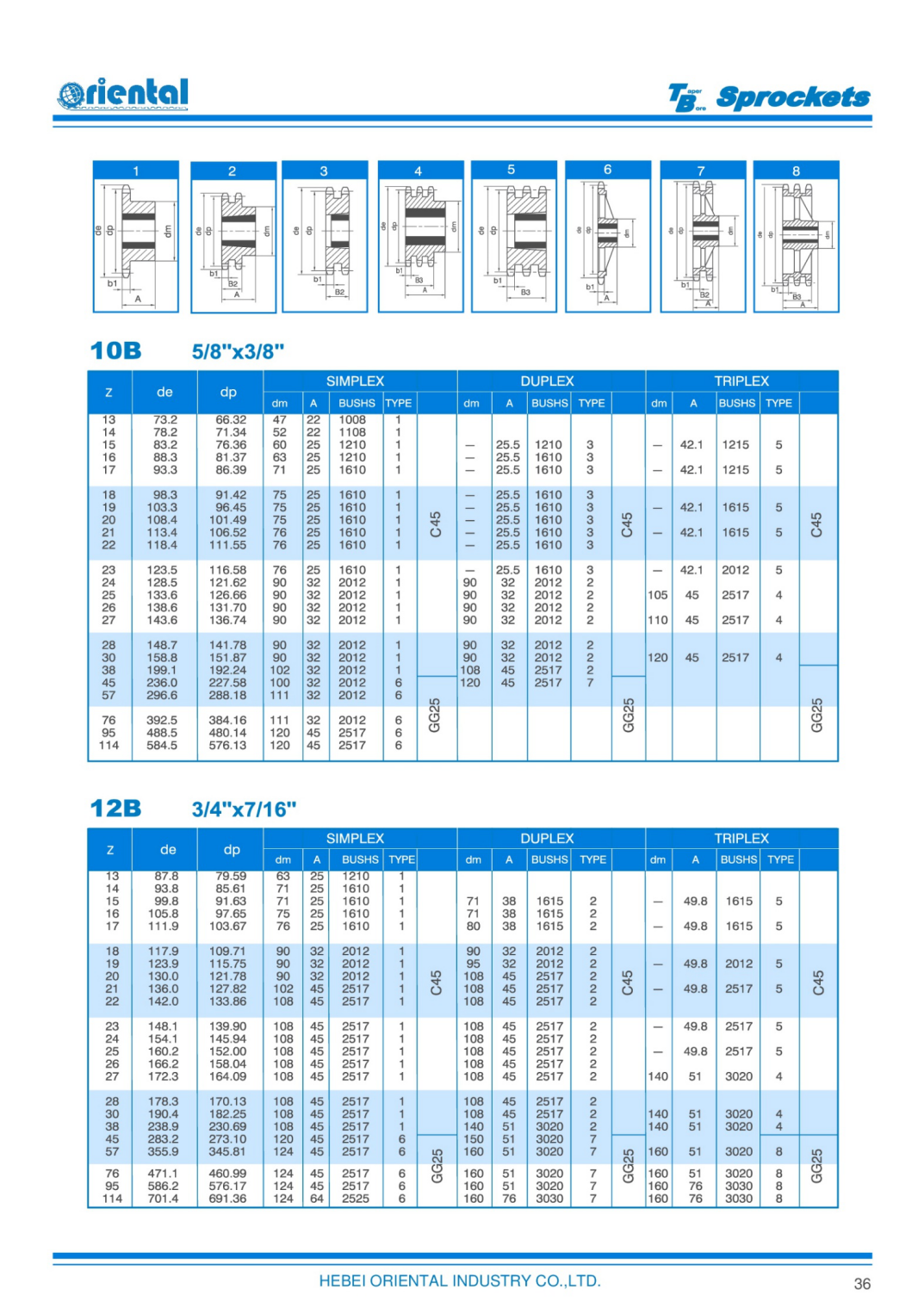

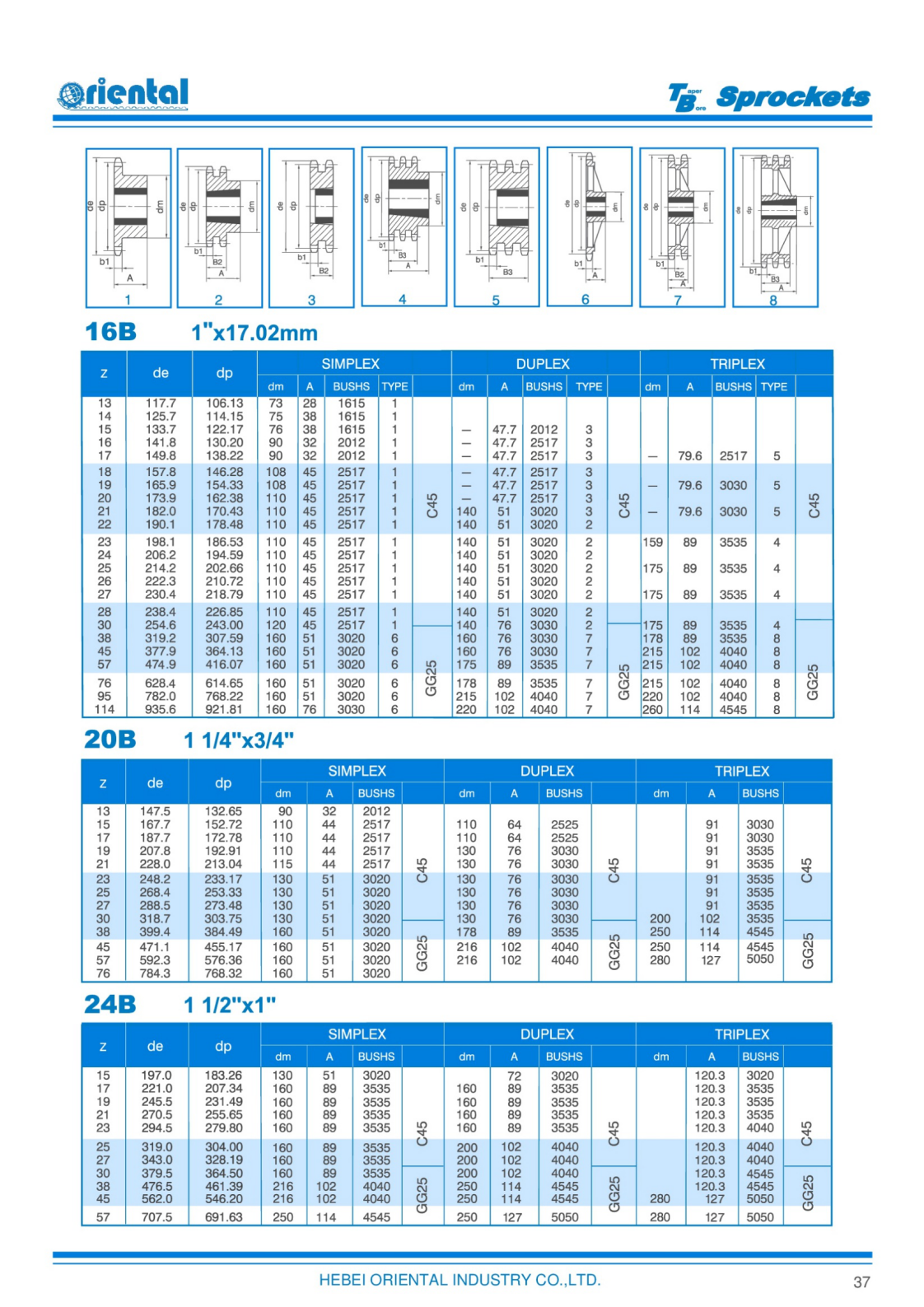

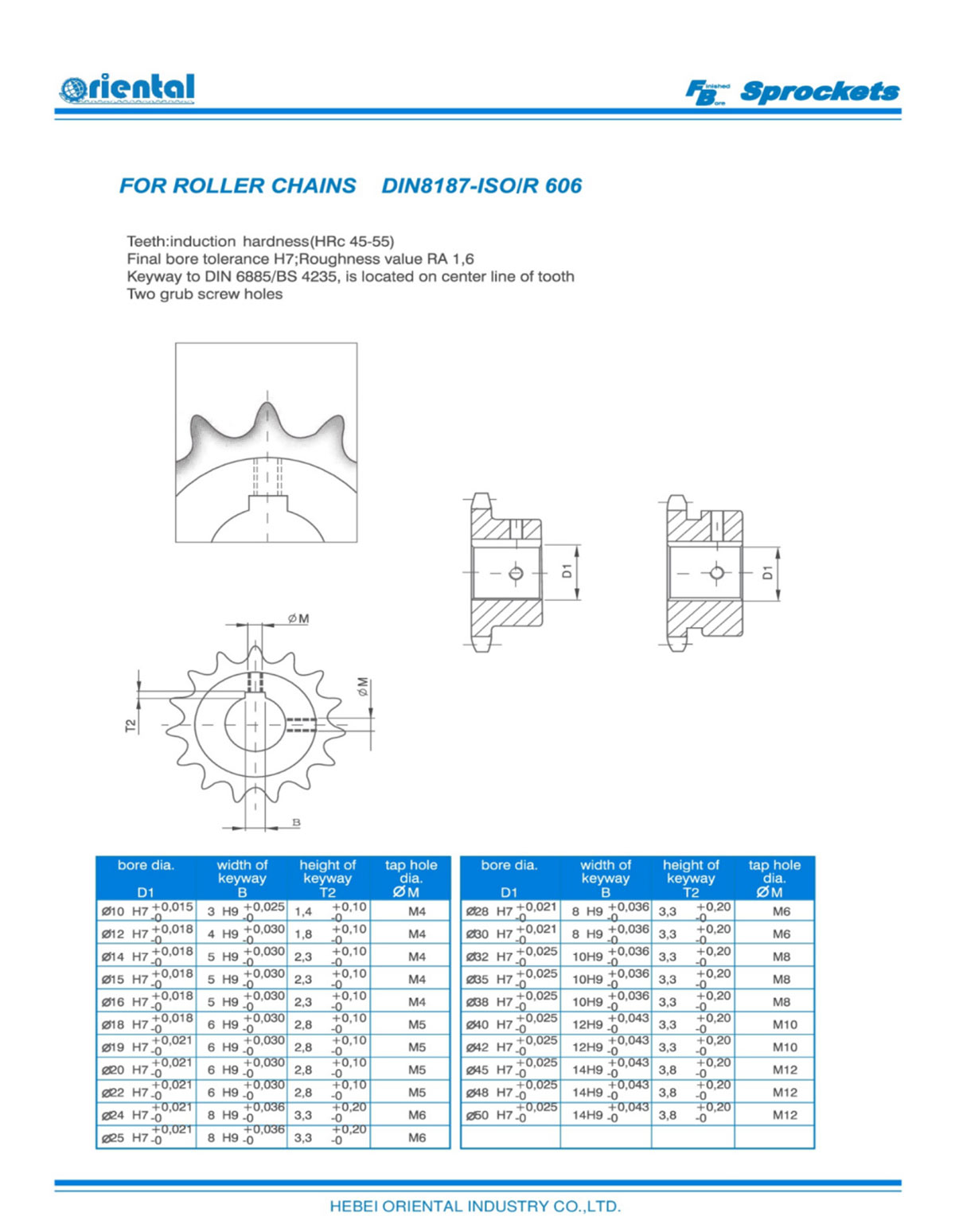

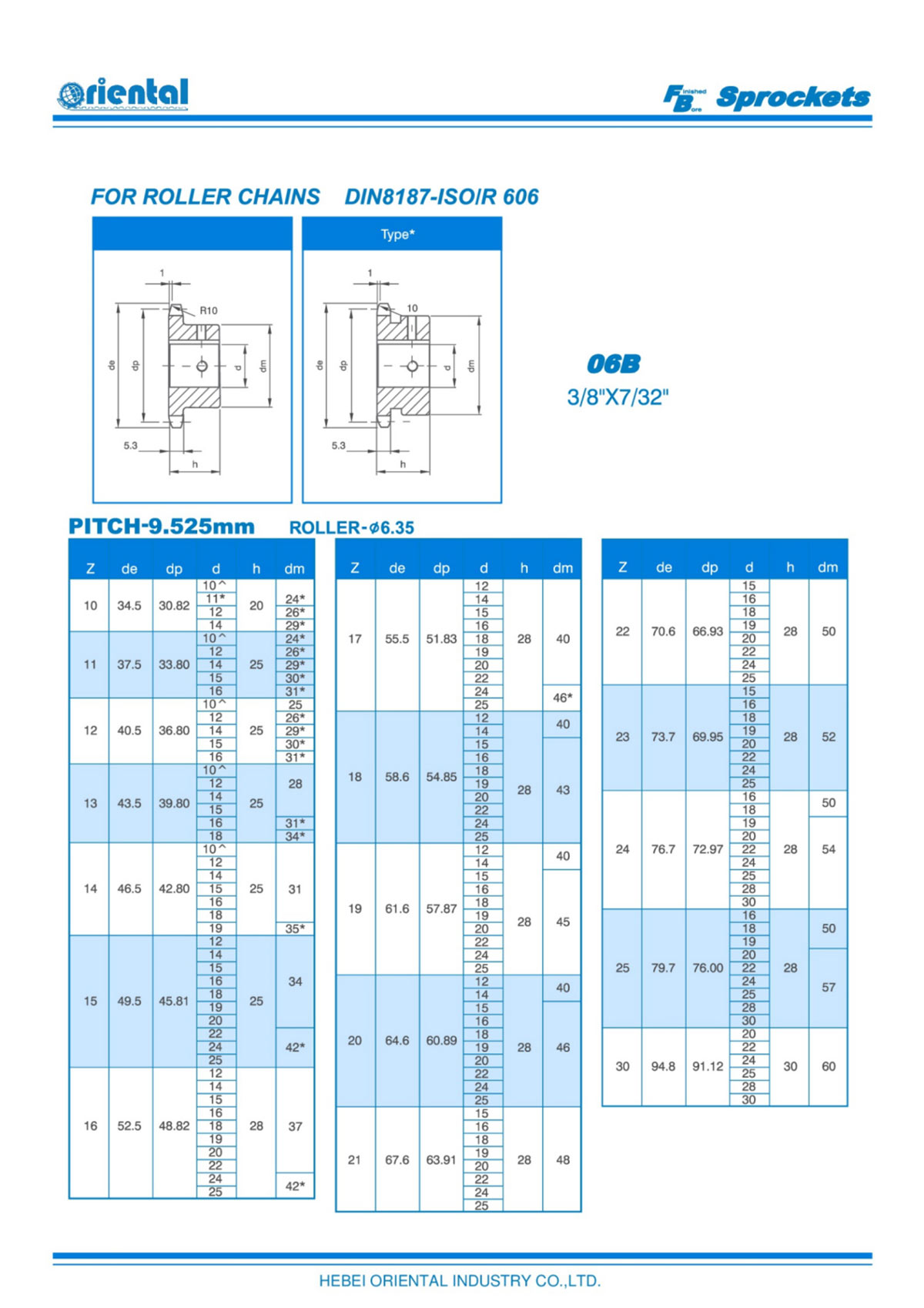

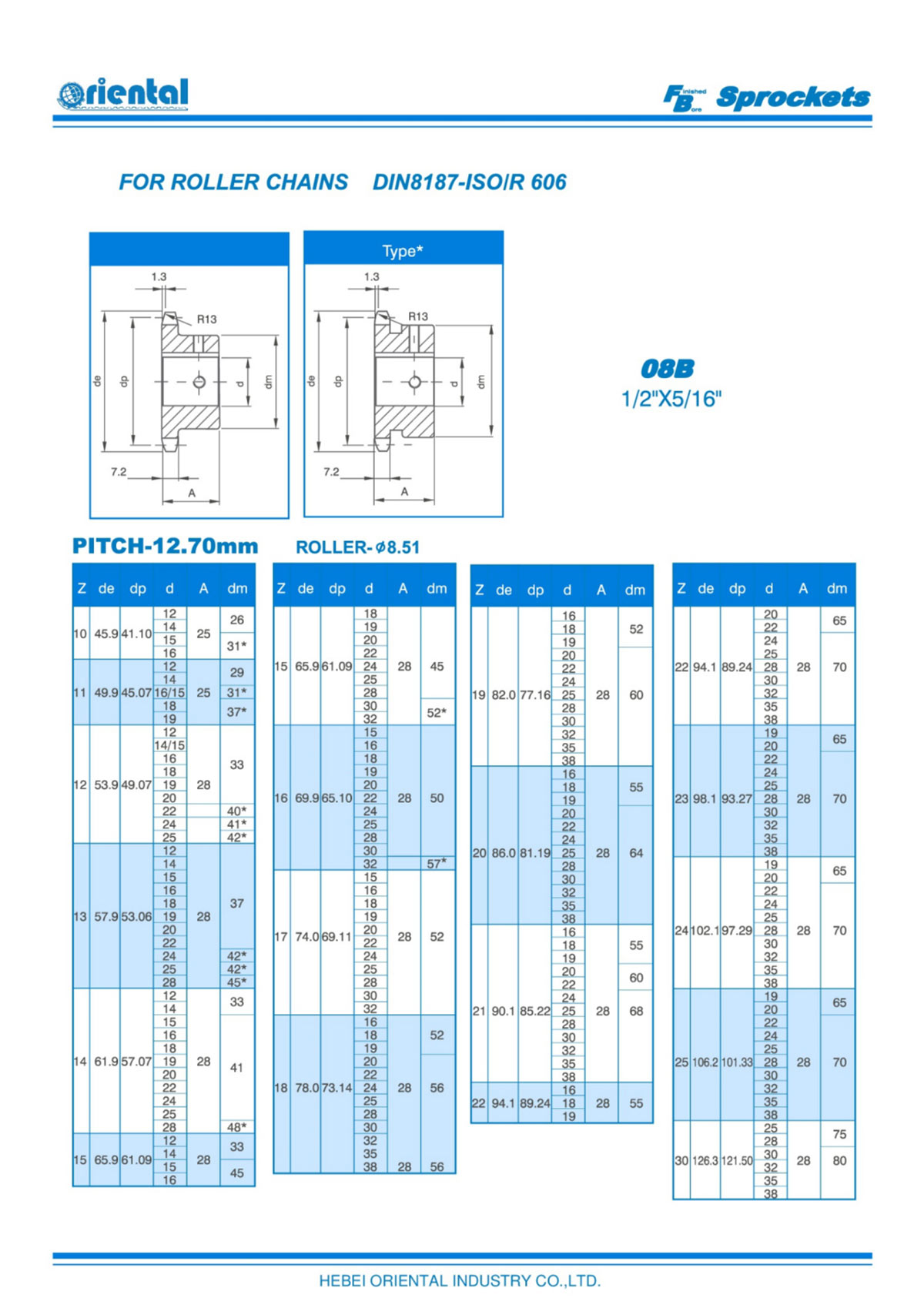

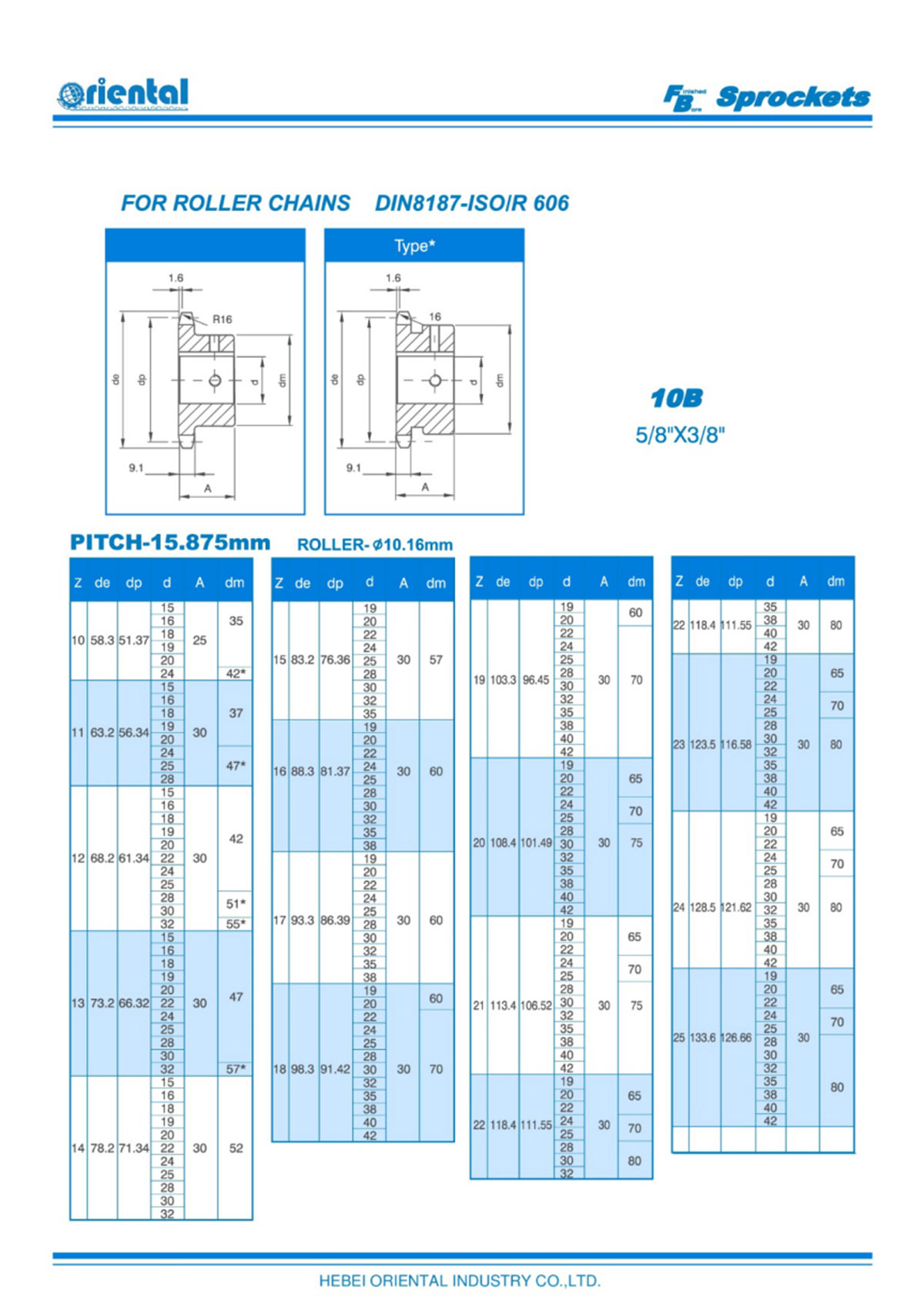

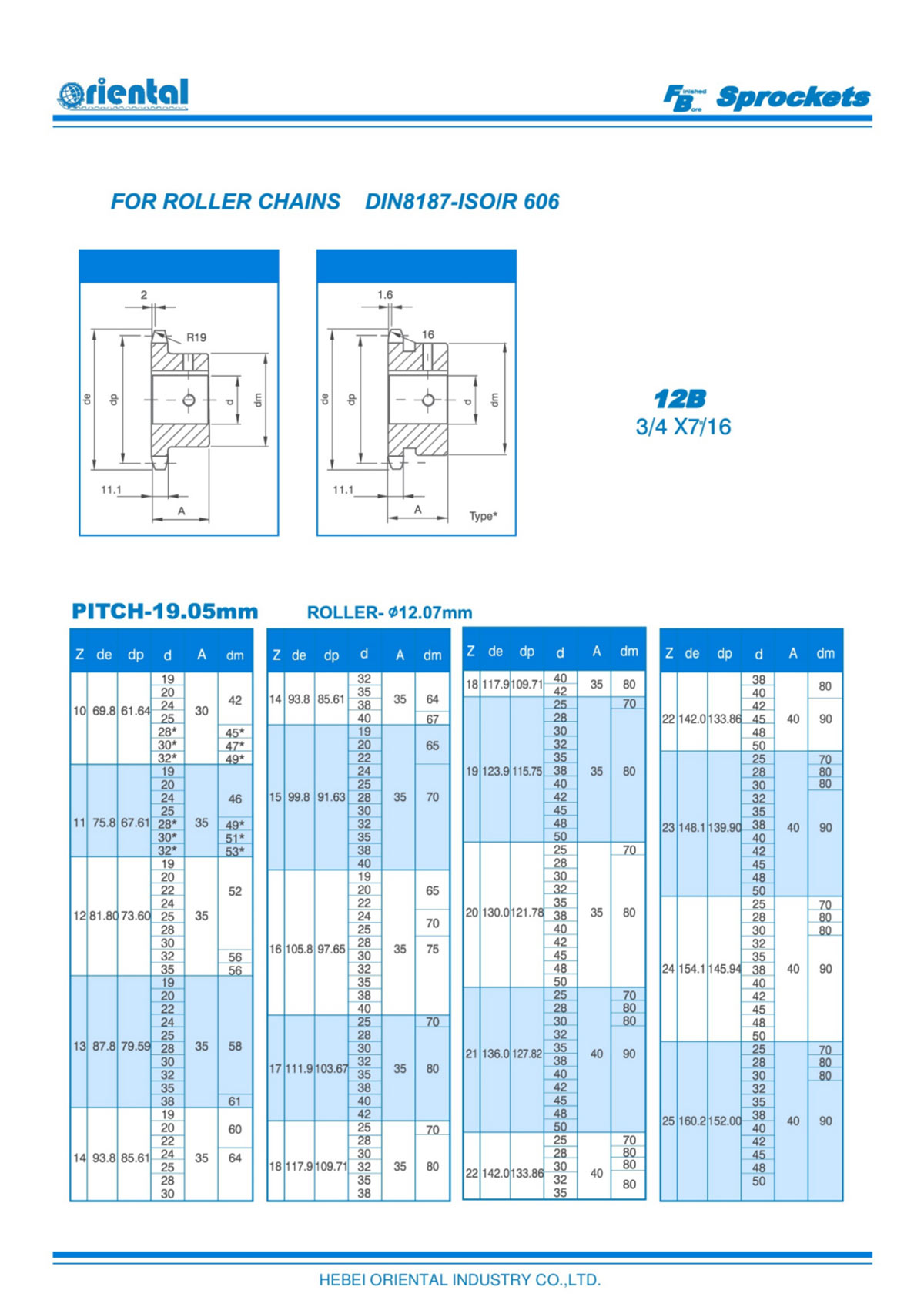

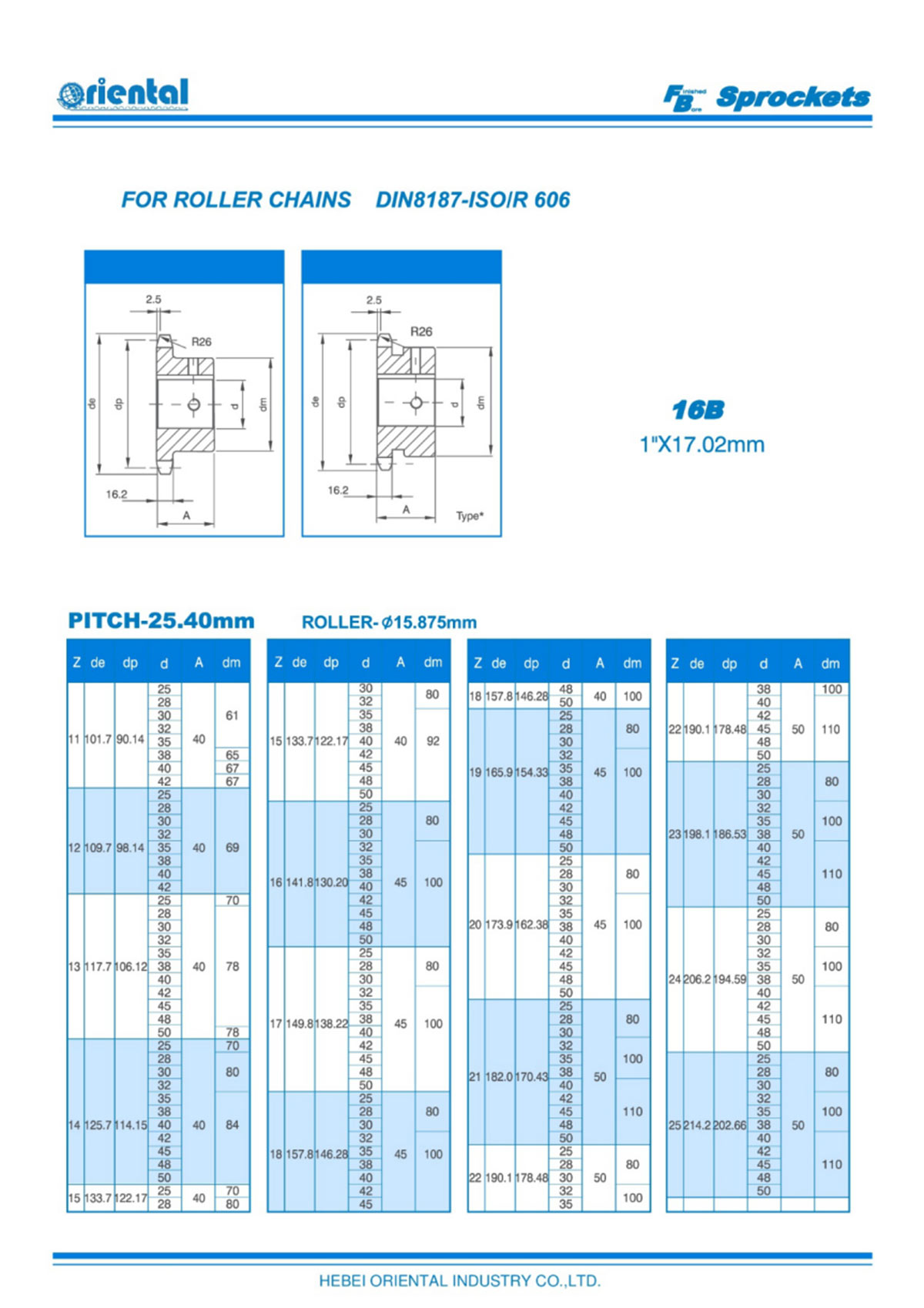

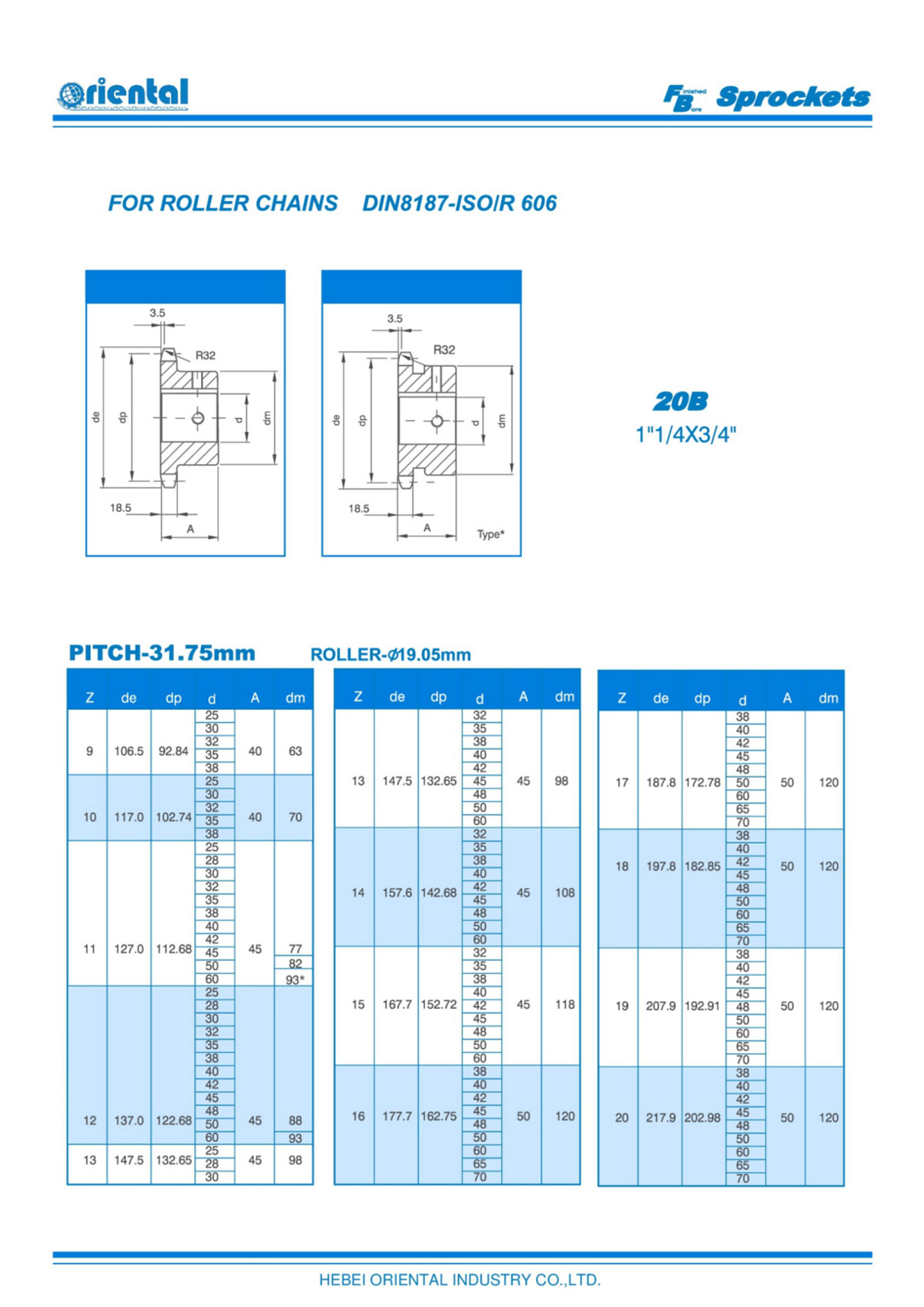

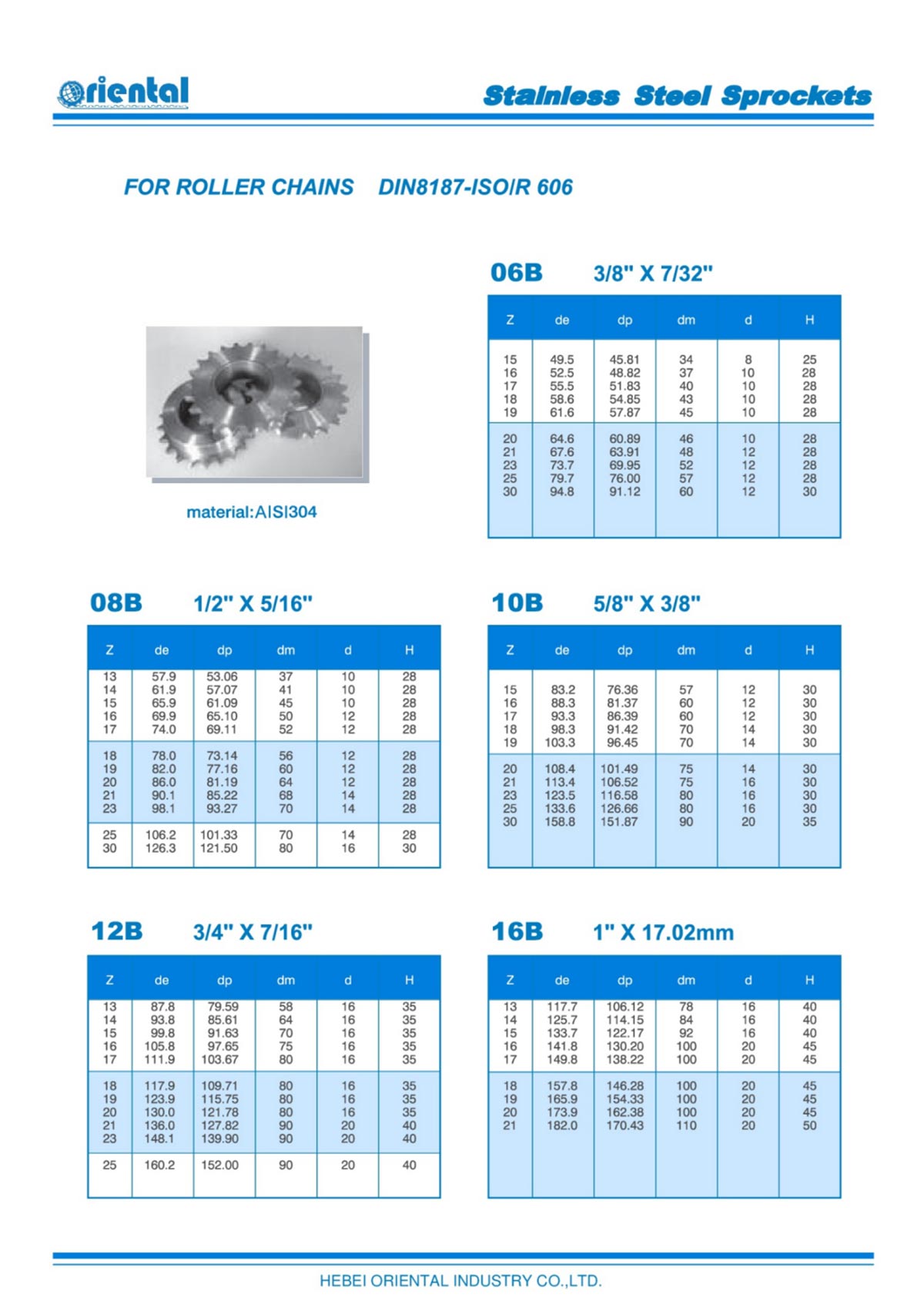

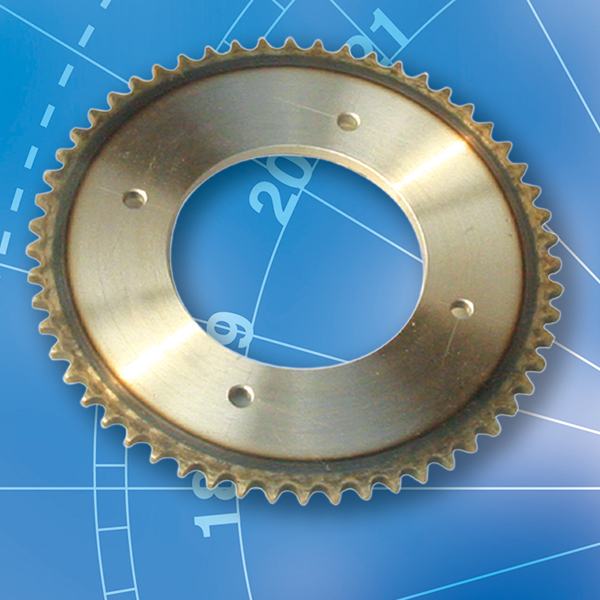

Finishied bore sprockets for roller chains,teech: induction hardness(hrc45-55),final bore tolerance H7; roughness value RA1.6,keyway to DIN 6885/BS4235,islocated on center line of tooth.Two grub screw holes.

06B(PITCH-9.525MM) 08B(PITCH-12.70MM) 10B(PITCH-15.875MM) 12B(PITCH-19.05MM) 16B (PITCH-25.4MM) 20B (PITCH-31.75MM)

-

-

In order to satisfy various types customer, we may request according to the customer to provide the design and the production.

For example, this waste paper packaging machine,which is used for both cardboard, soft and hard plastic and the like material. The big throw in front with one Clear control panel, making the press very easy to operate.

The press is equipped with a full detector that shows when it is to be emptied.

It is equipped with its own multipress button; presses four times instead of one.

It is easy to tie the ball. The ball can be stacked and takes minimal with space. This provides good storage capacity and transport economy.

Standard components and proven pressure technology ensure low

Operating expenses

This best seller sells more than 5,000 units in the Scandinavian countries. This is an electromechanical packaging baler. Small shops (grocery stores) are often chosen because they require only 1.6 square meters of space and the paper bags can weigh up to 250 kilograms.

Other industries are also very suitable mainly for office buildings, warehouses, production facilities, shopping malls, hotels and so on.

It is suitable for cardboard, soft and hard plastic materials.

The front of the baler has a clear control panel that makes the baler very easy to operate. The baler is equipped with a complete detector that shows when it is empty (remove paper bags).

It is equipped with multi-function buttons with four pressure levels, not one. So it's easy to pack. Paper bags can be stacked and take up very little space. This provides good storage capacity and transportation economy. Standard components and proven pressure technology ensure low operating costs.

-

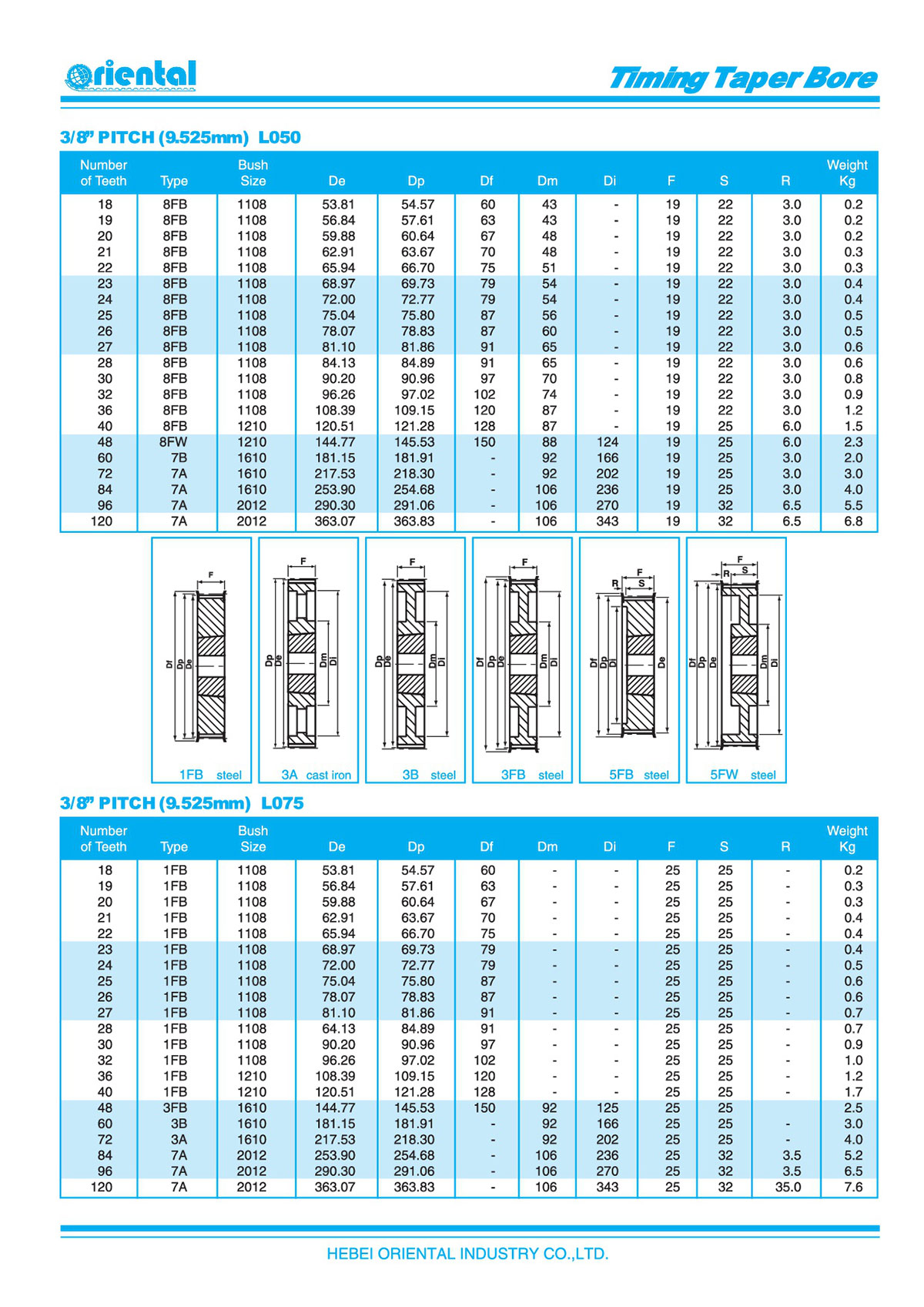

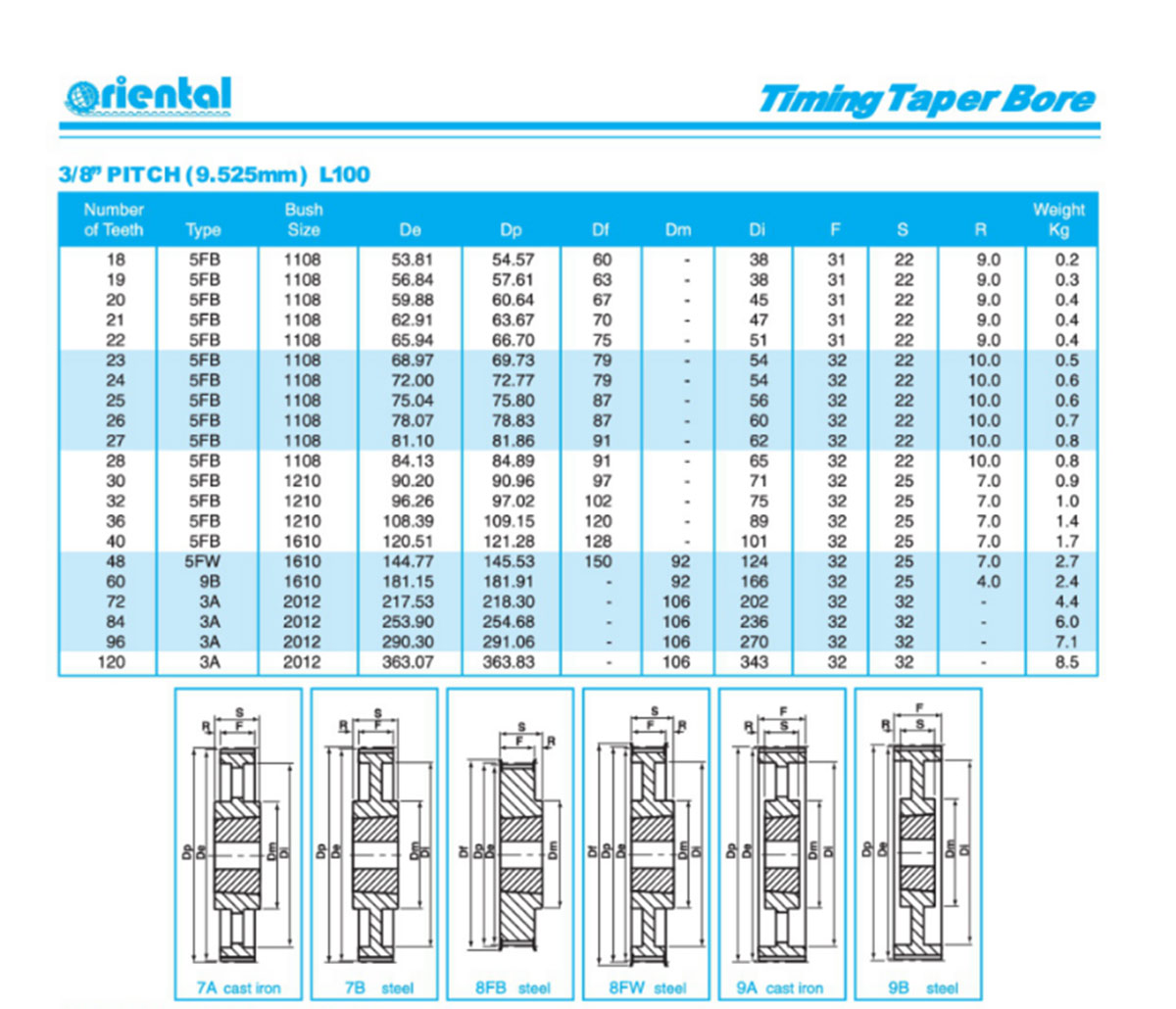

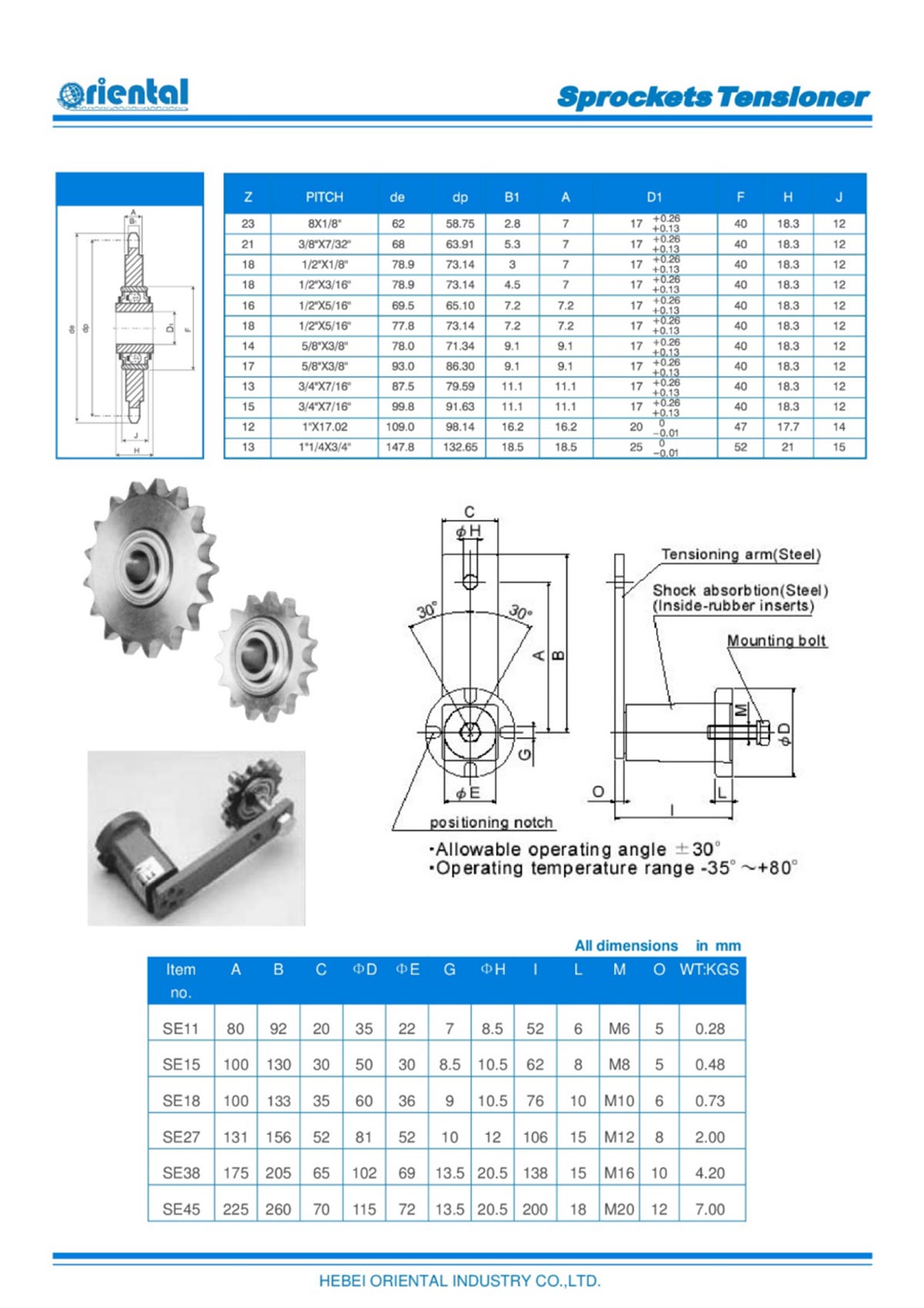

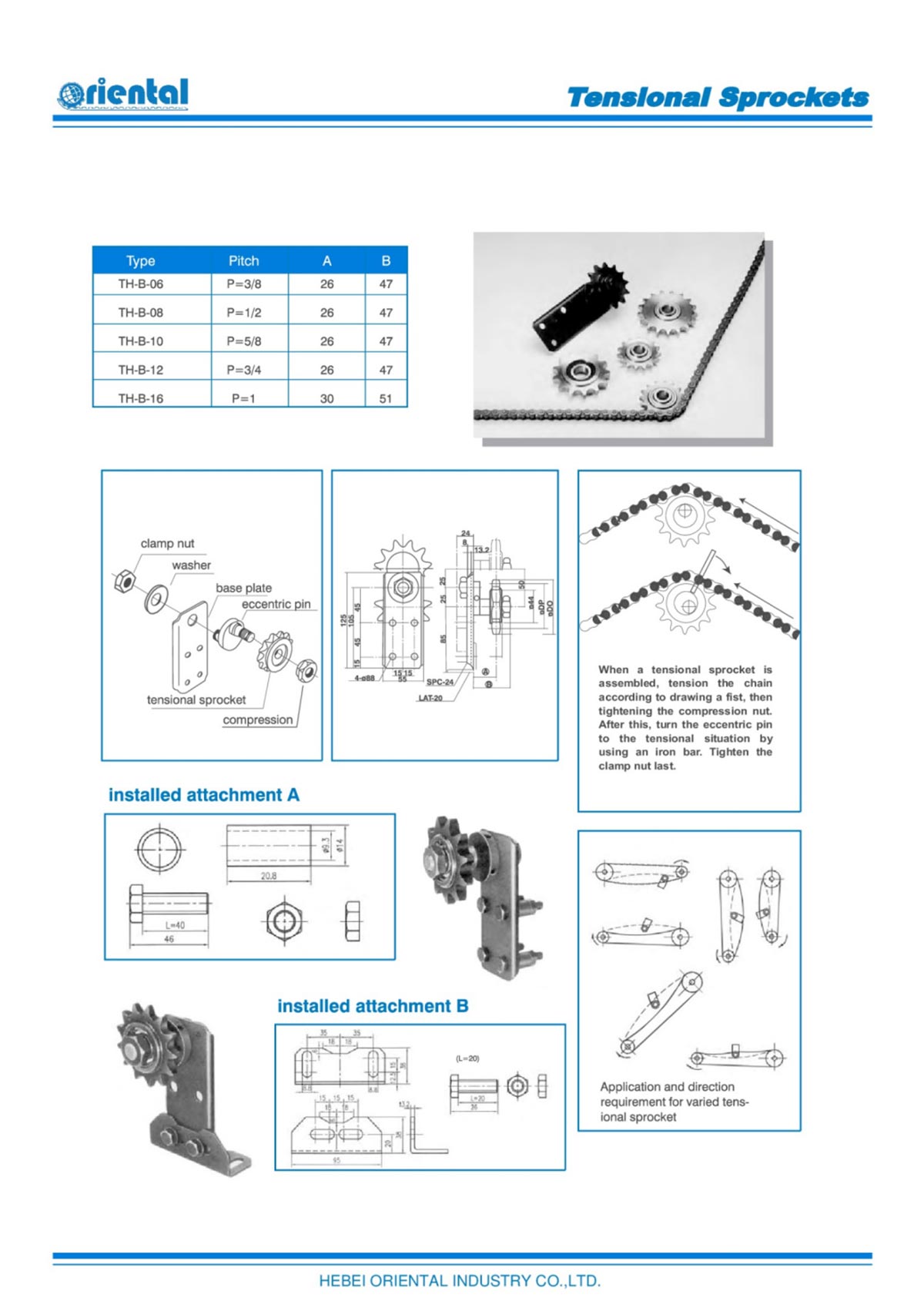

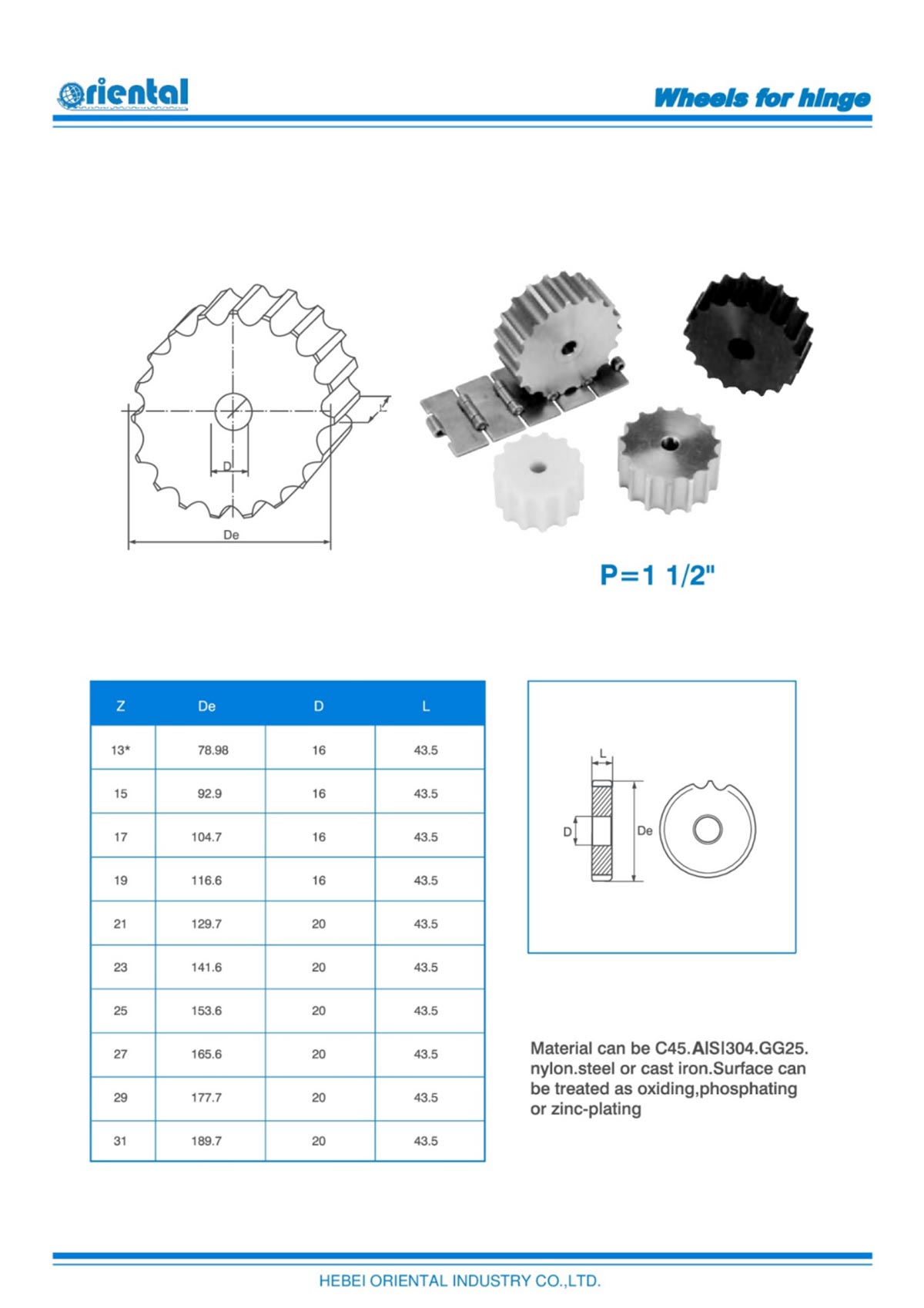

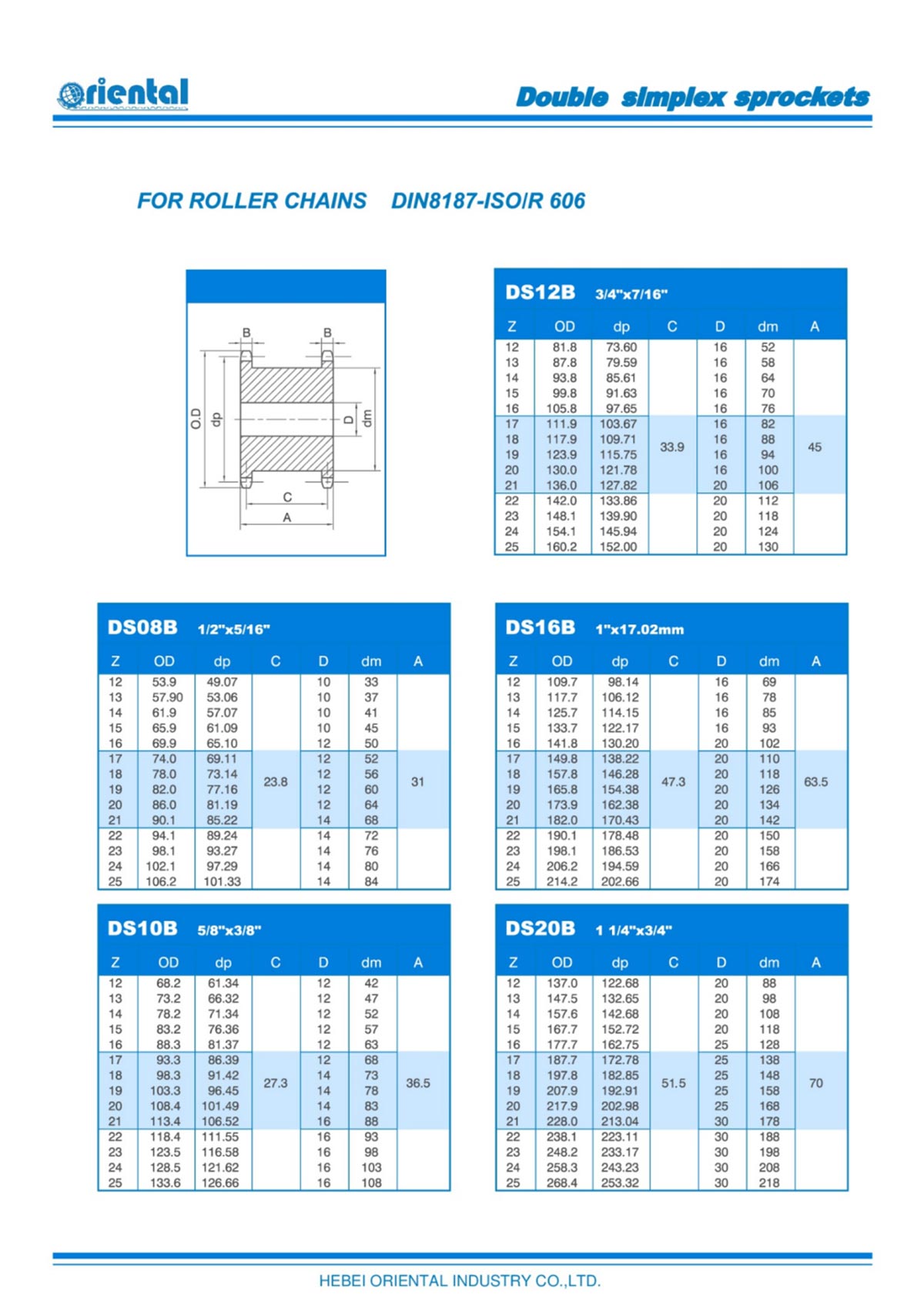

Sprockets Tensioner, Wheels for hinge sprockets, Double simplex sprockets, all kinds of conveyor sprockets with long pitch, stainless steel sprockets