-

-

-

-

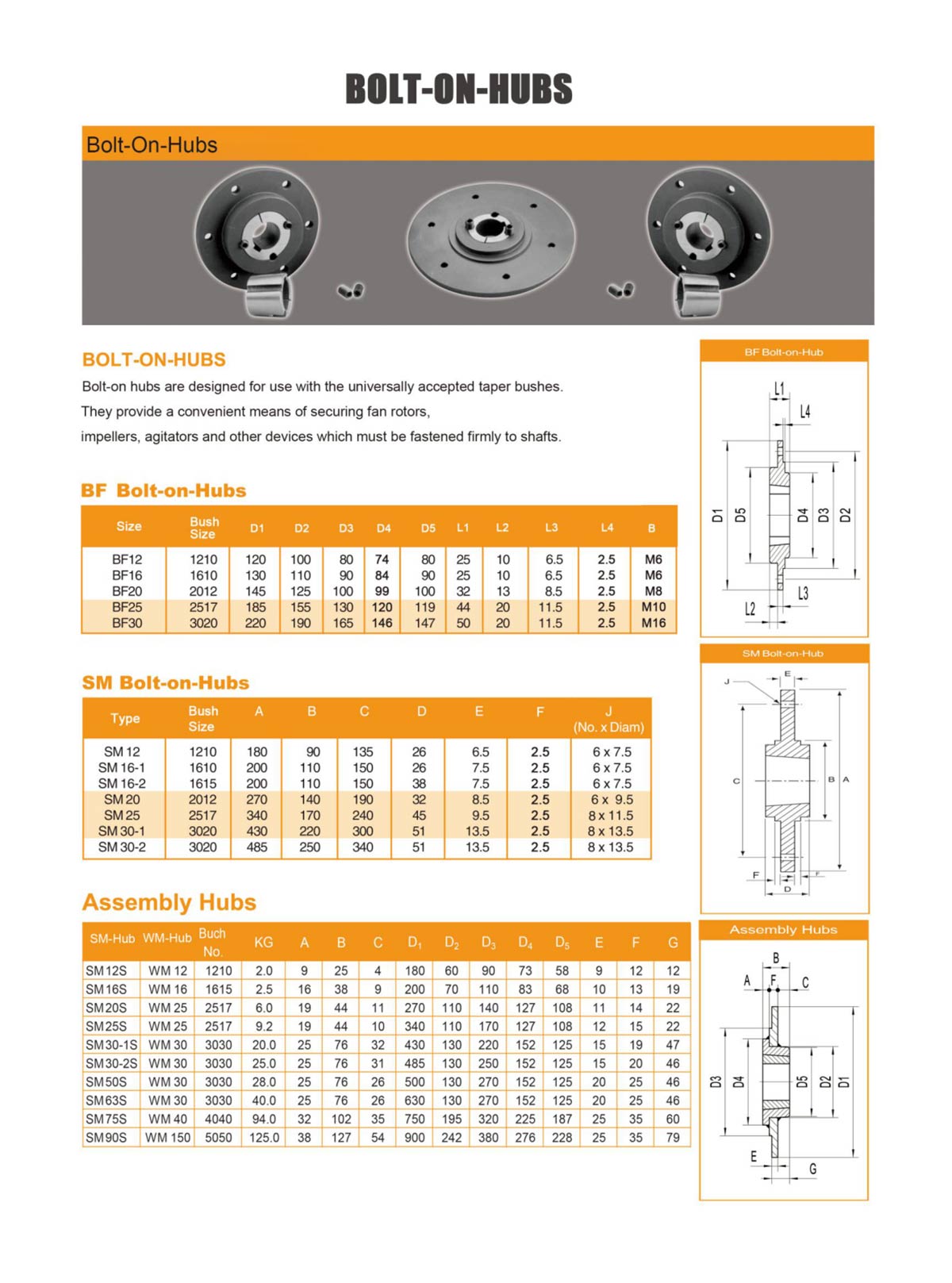

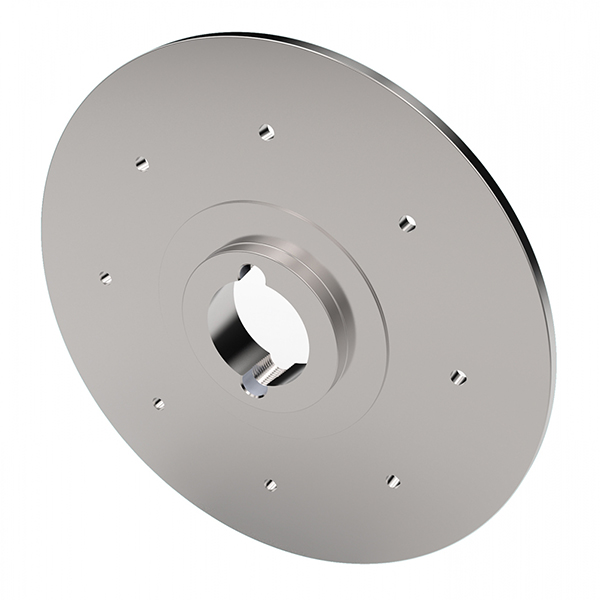

Bolt-on-hubs are designed for use with the universally accepted taper bushes .They provide a convenient means

of securing fan rotors.

They provide a convenient means of securing fan rotors.

Impeller,agitators and other devices which must be fastened firmly to shafts.

BF Bolt-on-Hubs

SM Bolt-on-Hubs

Assembly Hubs

-

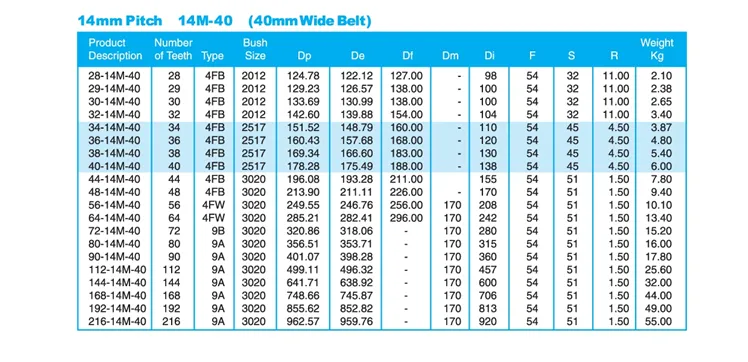

HTD Taper Bore Timing Pulleys

14mm Pitch 14M-40(40mm Wide Belt) 14mm Pitch 14M-55(55mm Wide Belt)

14mm Pitch 14M-85(85mm Wide Belt) 14mm Pitch 14M-115(115mm Wide Belt)

14mm Pitch 14M-170(170mm Wide Belt)

Material: Steel, Cast Iron

We can supply different size timing belt pulleys.

HTD 14M-40 pulley for belt width 40 mm

28-14M-40, 30-14M-40, 32-14M-40, 34-14M-40, 36-14M-40, 38-14M-40,

40-14M-40, 44-14M-40, 48-14M-40, 56-14M-40, 64-14M-40, 72-14M-40,

80-14M-40, 90-14M-40, 112-14M-40, 144-14M-40, 168-14M-40, 192-14M-40

HTD 14M-55 pulley for belt width 55 mm

28-14M-55, 30-14M-55, 32-14M-55, 34-14M-55, 36-14M-55, 38-14M-55,

40-14M-55, 44-14M-55, 48-14M-55, 56-14M-55, 64-14M-55, 72-14M-55,

80-14M-55, 90-14M-55, 112-14M-55, 144-14M-55, 168-14M-55, 192-14M-55

HTD 14M-85 pulley for belt width 85 mm

28-14M-85, 30-14M-85, 32-14M-85, 34-14M-85, 36-14M-85, 38-14M-85,

40-14M-85, 44-14M-85, 48-14M-85, 56-14M-85, 64-14M-85, 72-14M-85,

80-14M-85, 90-14M-85, 112-14M-85, 144-14M-85, 168-14M-85, 192-14M-85

-

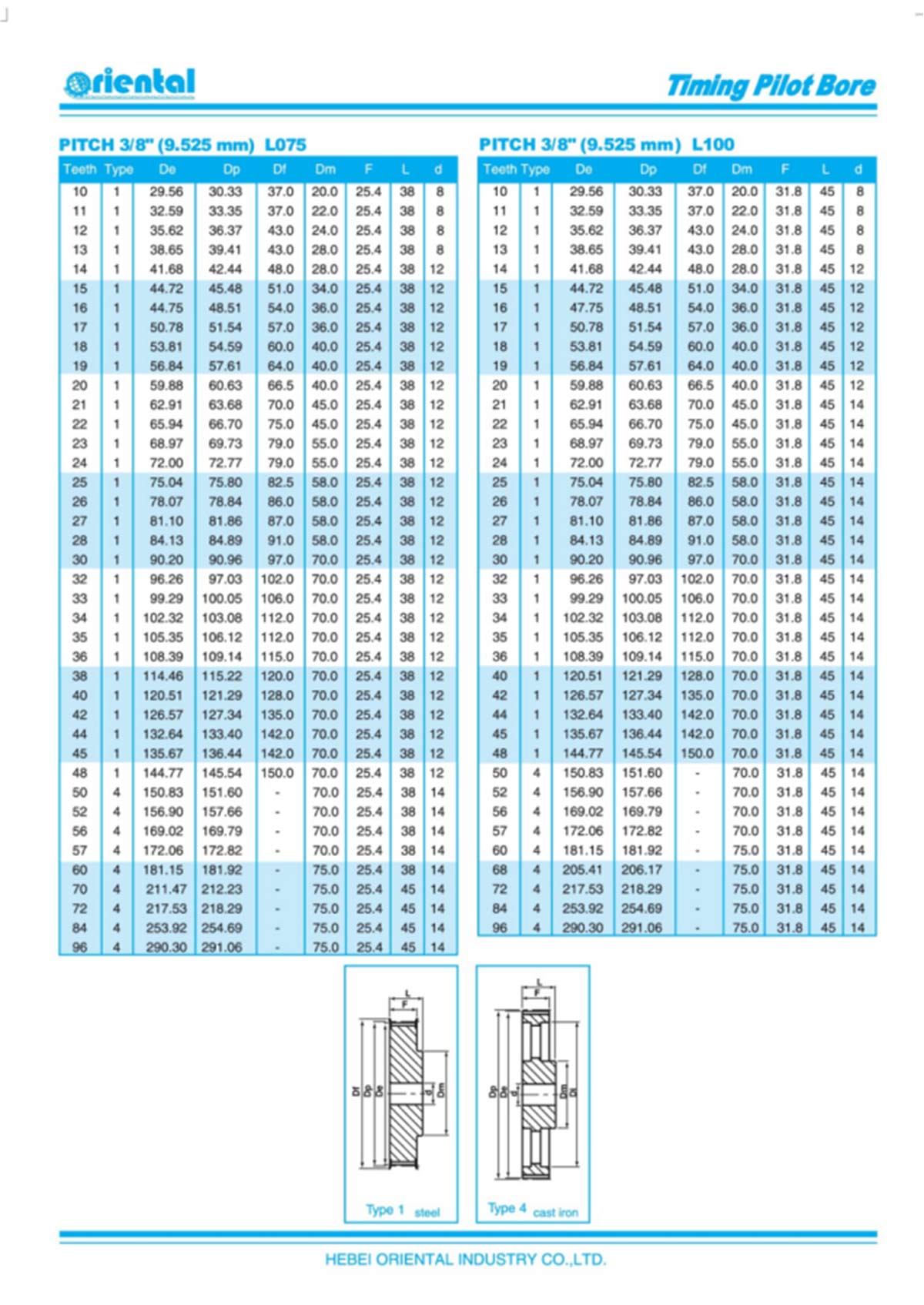

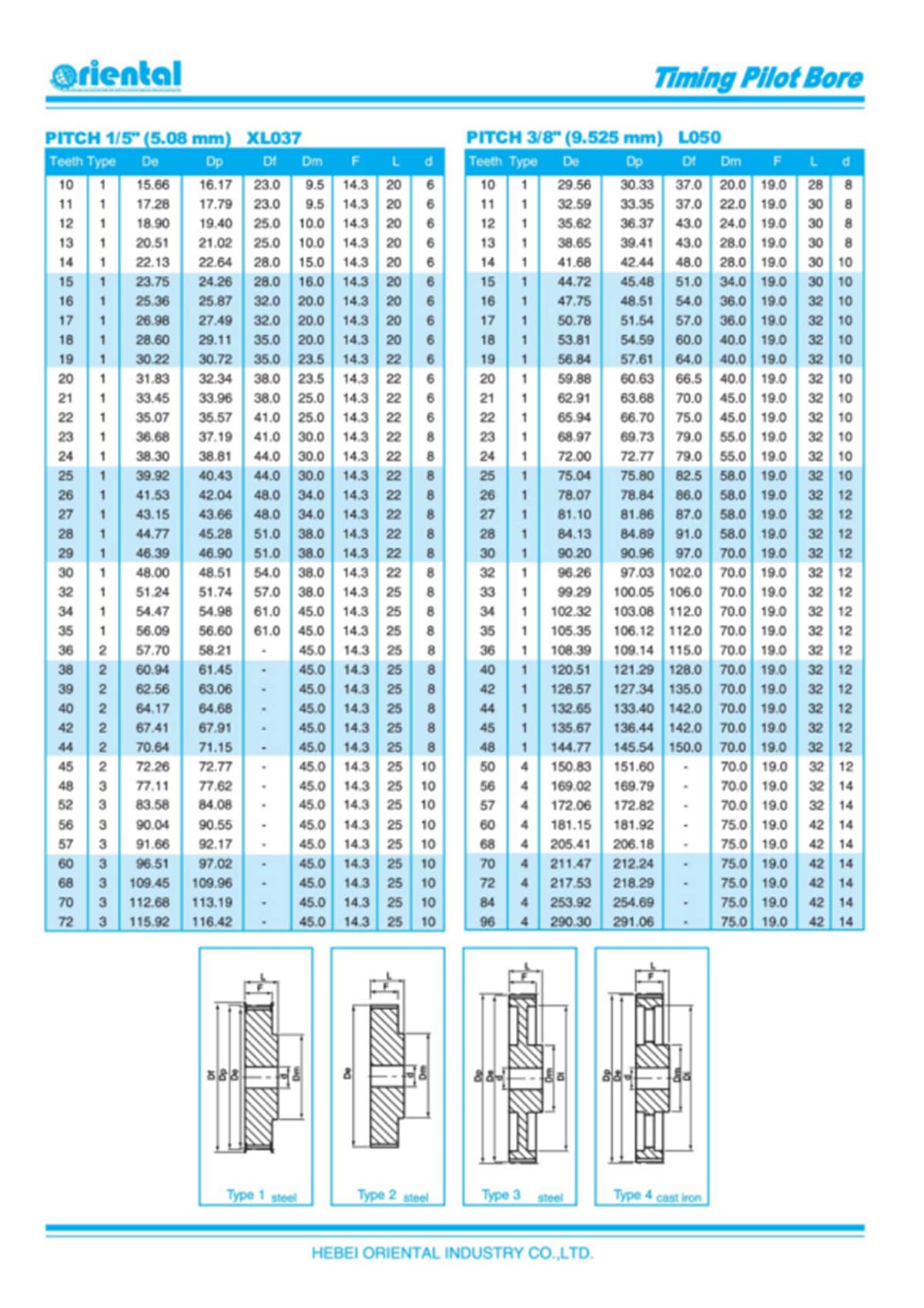

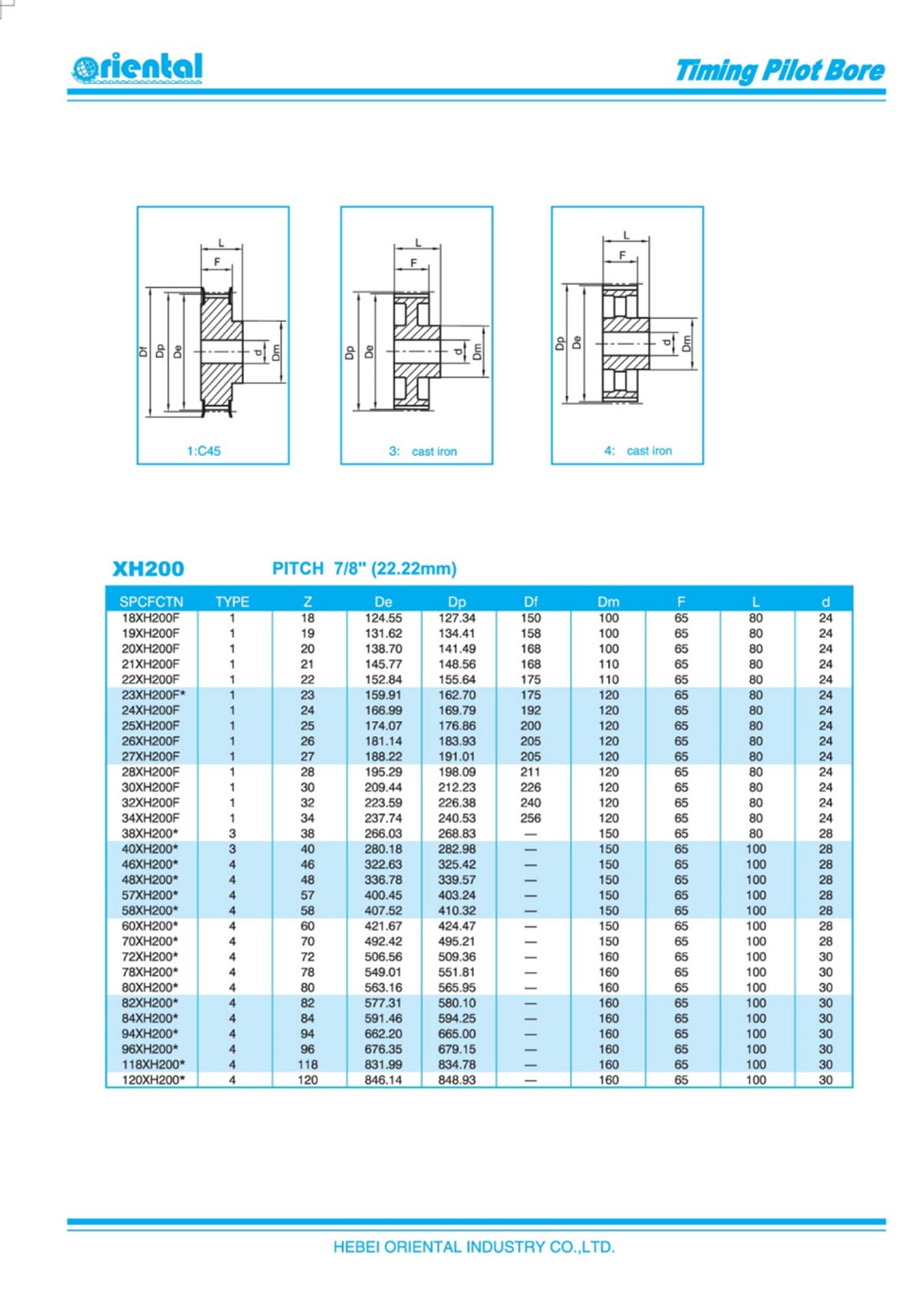

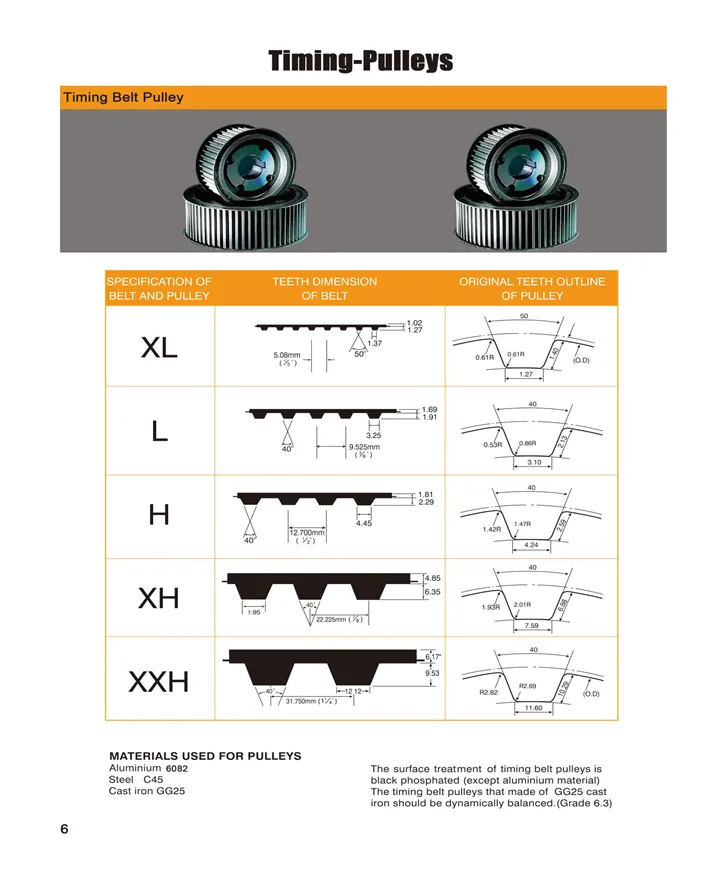

The timing pulley is the mechanical part used to transmit power between the crankshaft and camshaft of the engine.

It is usually made of aluminum or steel and contains teeth that mesh with the timing belt to ensure proper synchronization between the two shafts.

The pulley is mounted on the end of the camshaft and is responsible for driving the timing belt which in turn drives the camshaft.

This allows the valves in the engine to open and close at the appropriate times, ensuring optimum engine performance.

Timing pulleys are found in a variety of engines, including those found in cars, trucks, and industrial equipment.

Materials used for timing pulleys Alumimium 6082 Steel C45 Cast iron GG25

The surface treatment of timing belt pulleys is black phosphate (except aluminum material).The timing belt pulleys that made of GG25 cast iron should be dynamically balanced. (Grade 6.3)

Product Name Aluminum Timing Pulley XL L H XH XXH T2.5 T5 T10 AT5 AT10 GT2 GT3 GT5 3M 5M 8M

Tooth timing Belt PulleyTeeth profile Trapezoidal toothed XL, L, H, XH, XXHT-toothed T2.5, T5, T10, T20

Arc toothed HTD3M, HTD5M, HTD8M, HTD14M, HTD20M, Gt2, Gt3, Gt5

Teeth Quantity 10-150 teeth or customized

Inner Bore 2-200mm H7 precision or customized

Belt width 4mm, 6mm, 9mm, 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 1/4”, 5/16”, 3/8”, 1/2”, 3/4”, 1”, 1.5”, 2”or customized

Material cast iron GG25 , steel C45, Aluminum 6061, 6082

Surface treatment Anodize, Black Oxide, Phosphate, Galvanization

-

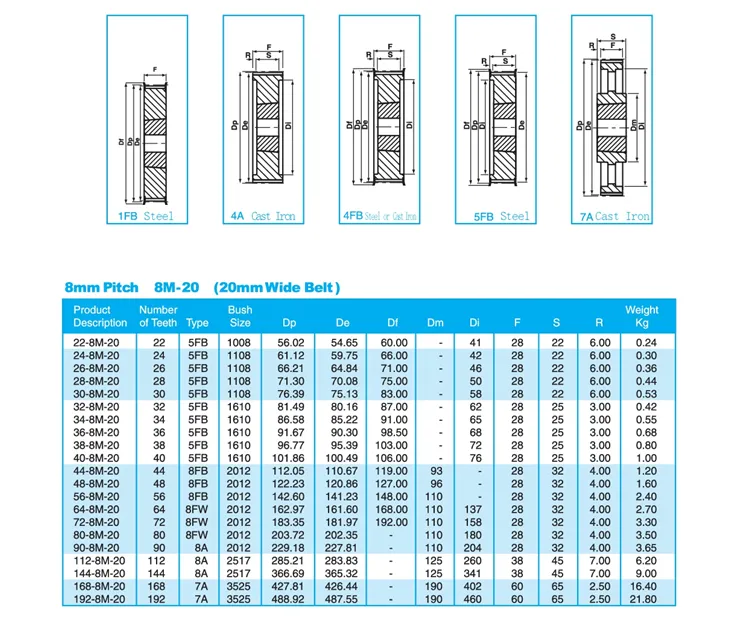

HTD Taper Bore Timing Pulleys 8mm Pitch 8M-20(20mm Wide Belt) 8mm Pitch 8M-30(30mm Wide Belt)

8mm Pitch 8M-50(50mm Wide Belt) 8mm Pitch 8M-85(85mm Wide Belt)

Material: Steel, Cast Iron

We can supply different size timing belt pulleys.

HTD 8M-20 pulley for belt width 20 mm

P22-8M-20, P24-8M-20, P26-8M-20, P28-8M-20, P30-8M-20, P32-8M-20,

P24-8M-20, P36-8M-20, P38-8M-20, P40-8M-20, P44-8M-20, P48-8M-20,

P56-8M-20, P64-8M-20, P72-8M-20, P80-8M-20,P 90-8M-20

HTD 8M-30 pulley for belt width 30 mm

P22-8M-30, P24-8M-30, P26-8M-30, P28-8M-30, P30-8M-30, P32-8M-30,

P34-8M-30, P36-8M-30, P38-8M-30, P40-8M-30, P44-8M-30, P48-8M-30,

P56-8M-30, P64-8M-30, P72-8M-30, P80-8M-30, P90-8M-30, P112-8M-30

HTD 8M-50 pulley for belt width 50 mm

P22-8M-50, P24-8M-50, P26-8M-50, P28-8M-50, P30-8M-50, P32-8M-50,

P34-8M-50, P36-8M-50, P38-8M-50, P40-8M-50, P44-8M-50, P48-8M-50,

P56-8M-50, P64-8M-50, P72-8M-50, P80-8M-50, P90-8M-50, P112-8M-50

HTD 8M-85 pulley for belt width 85 mm

P22-8M-85,P 24-8M-85, P26-8M-85, P28-8M-85, P30-8M-85, P32-8M-85

P34-8M-85, P36-8M-85, P38-8M-85, P40-8M-85, P44-8M-85, P48-8M-85

P56-8M-85,P 64-8M-85, P72-8M-85, P80-8M-85, P90-8M-85, P112-8M-85

-

-

-

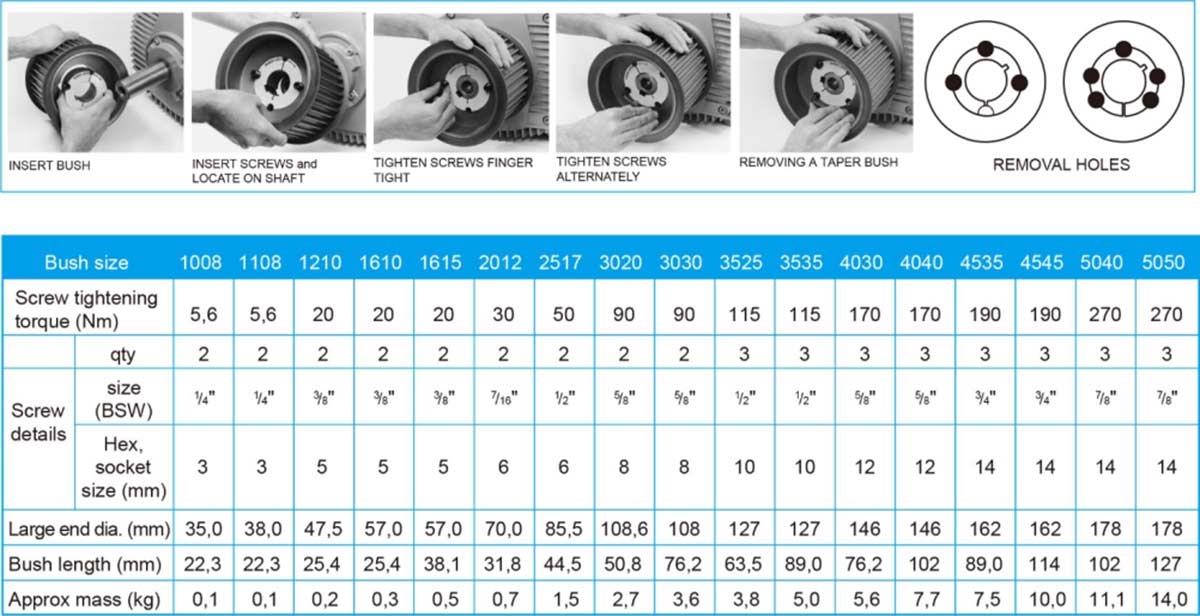

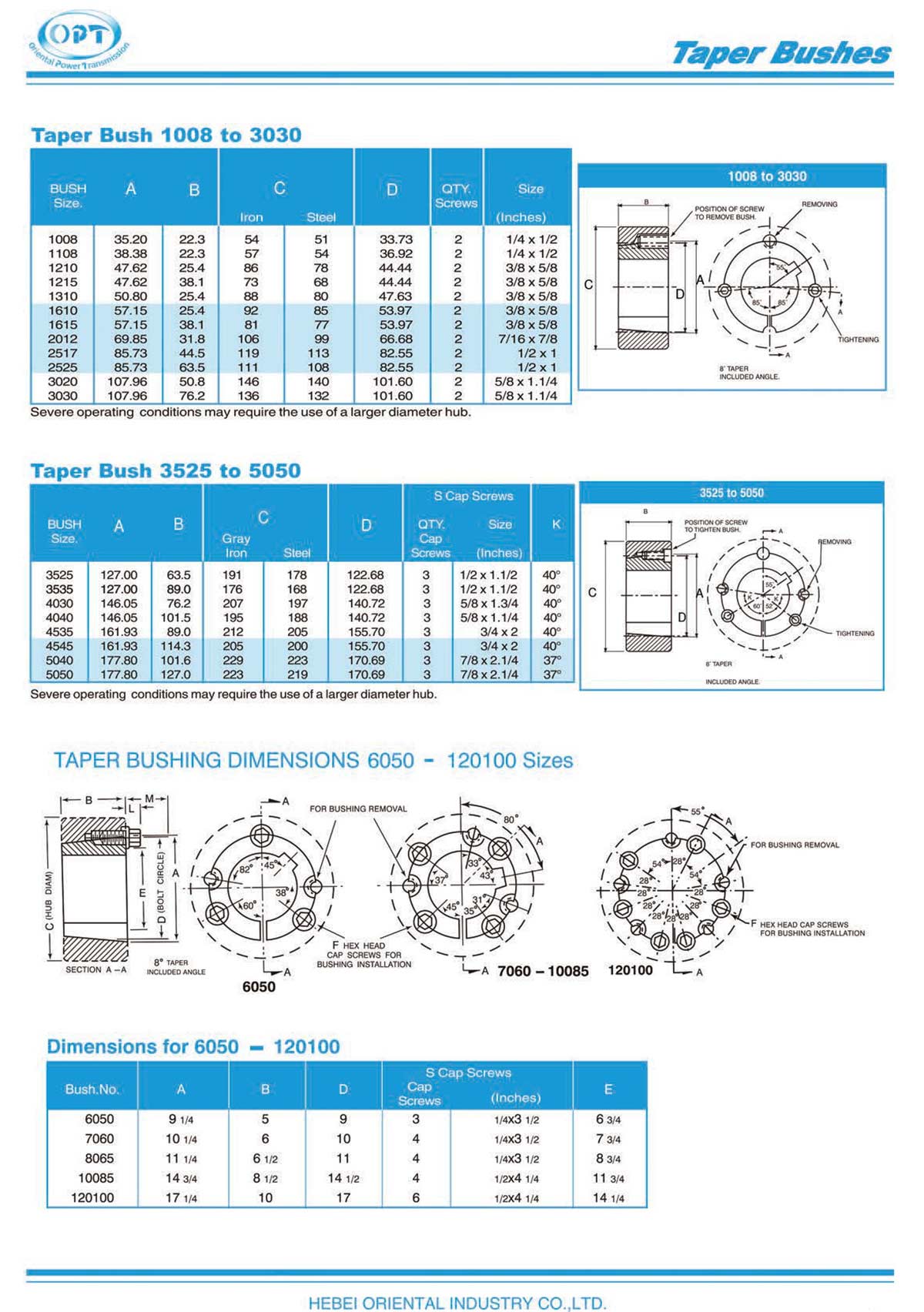

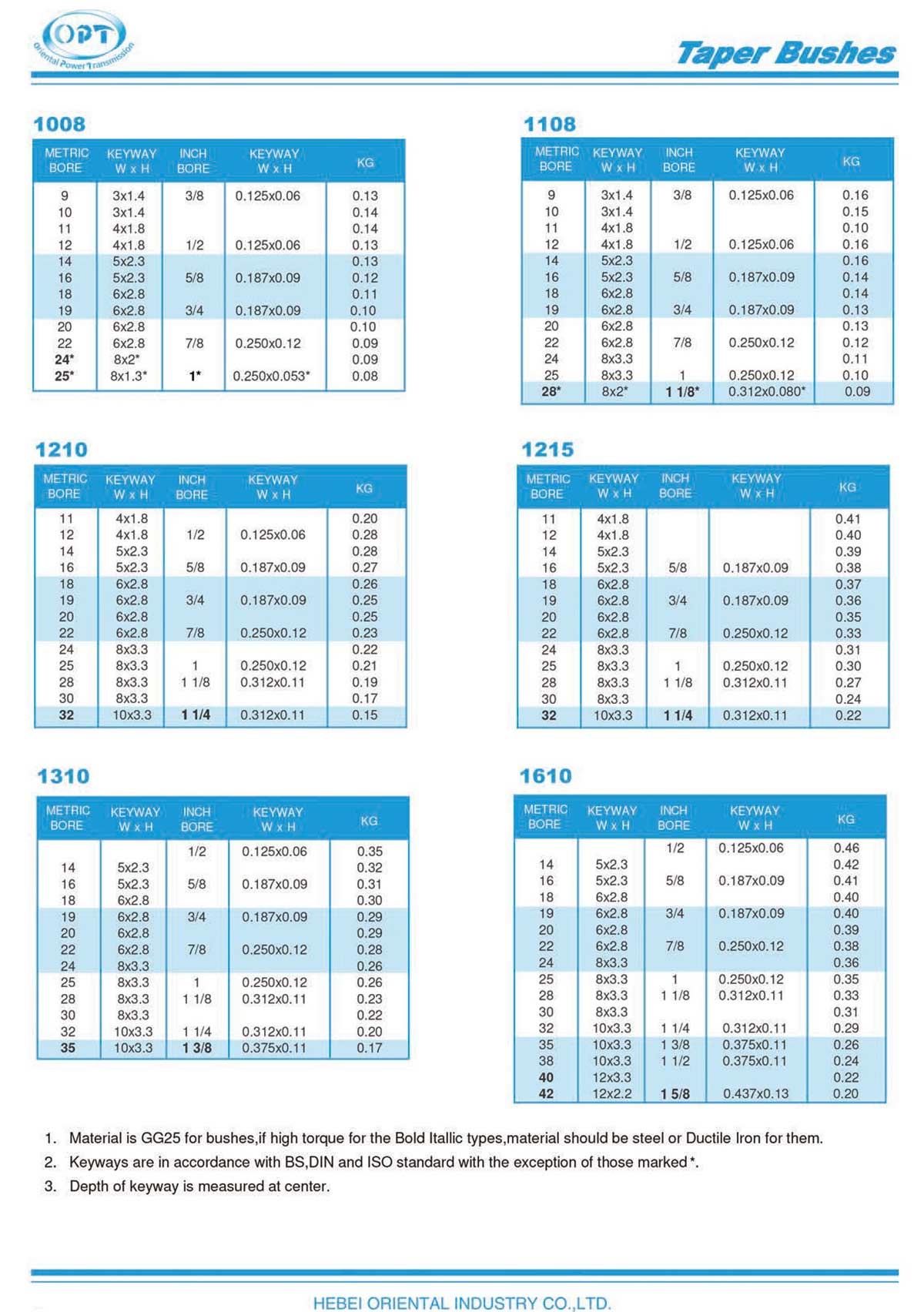

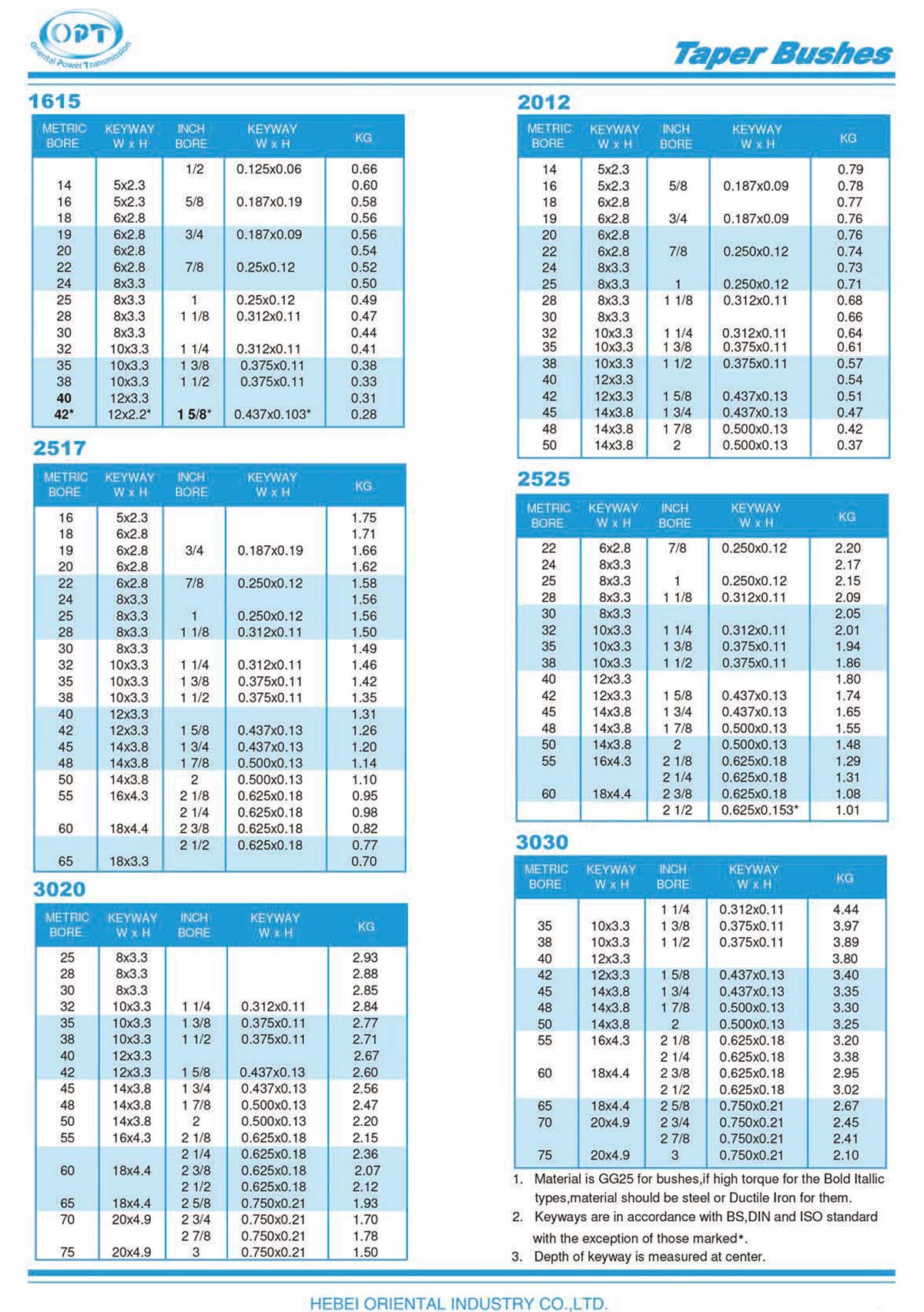

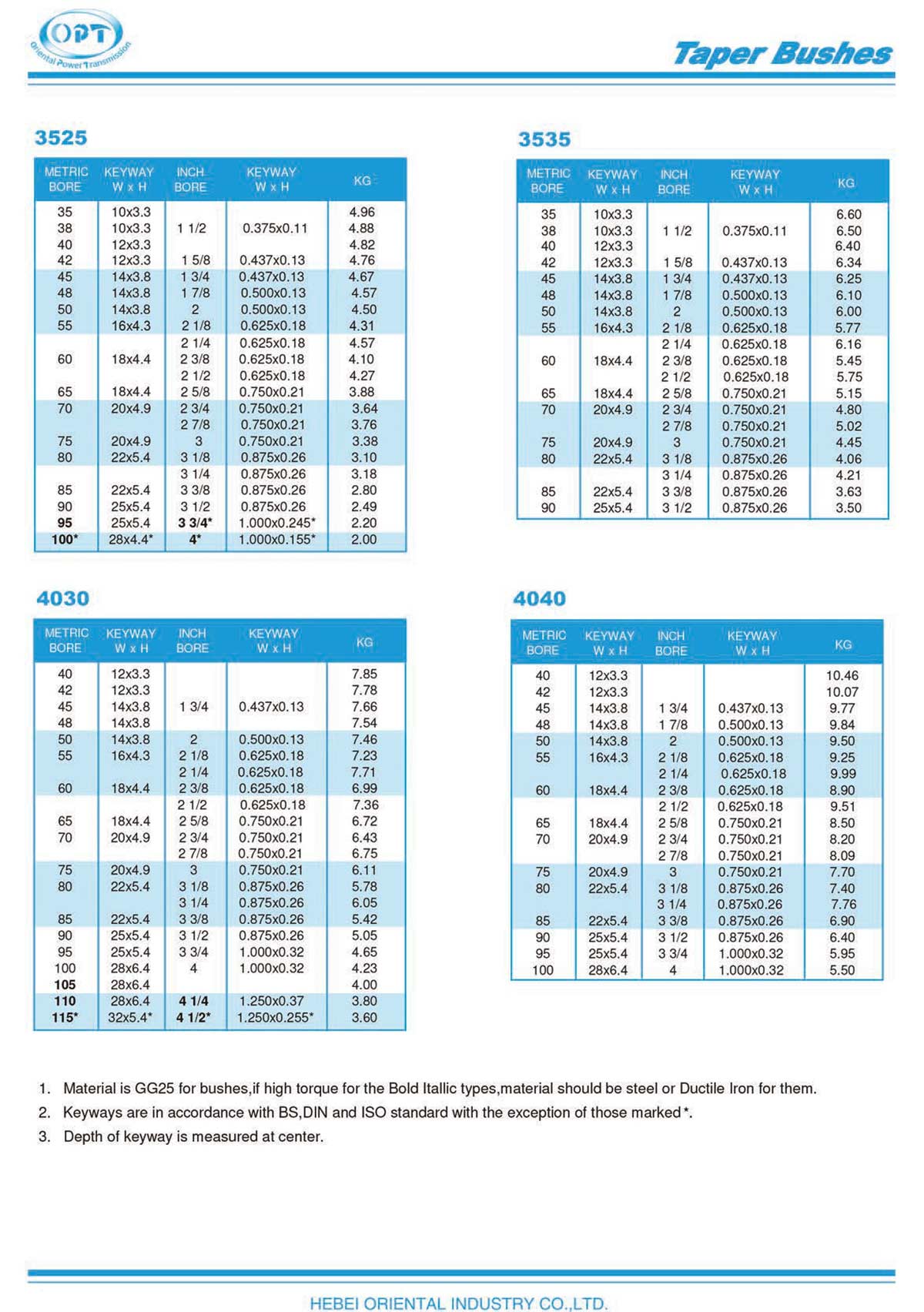

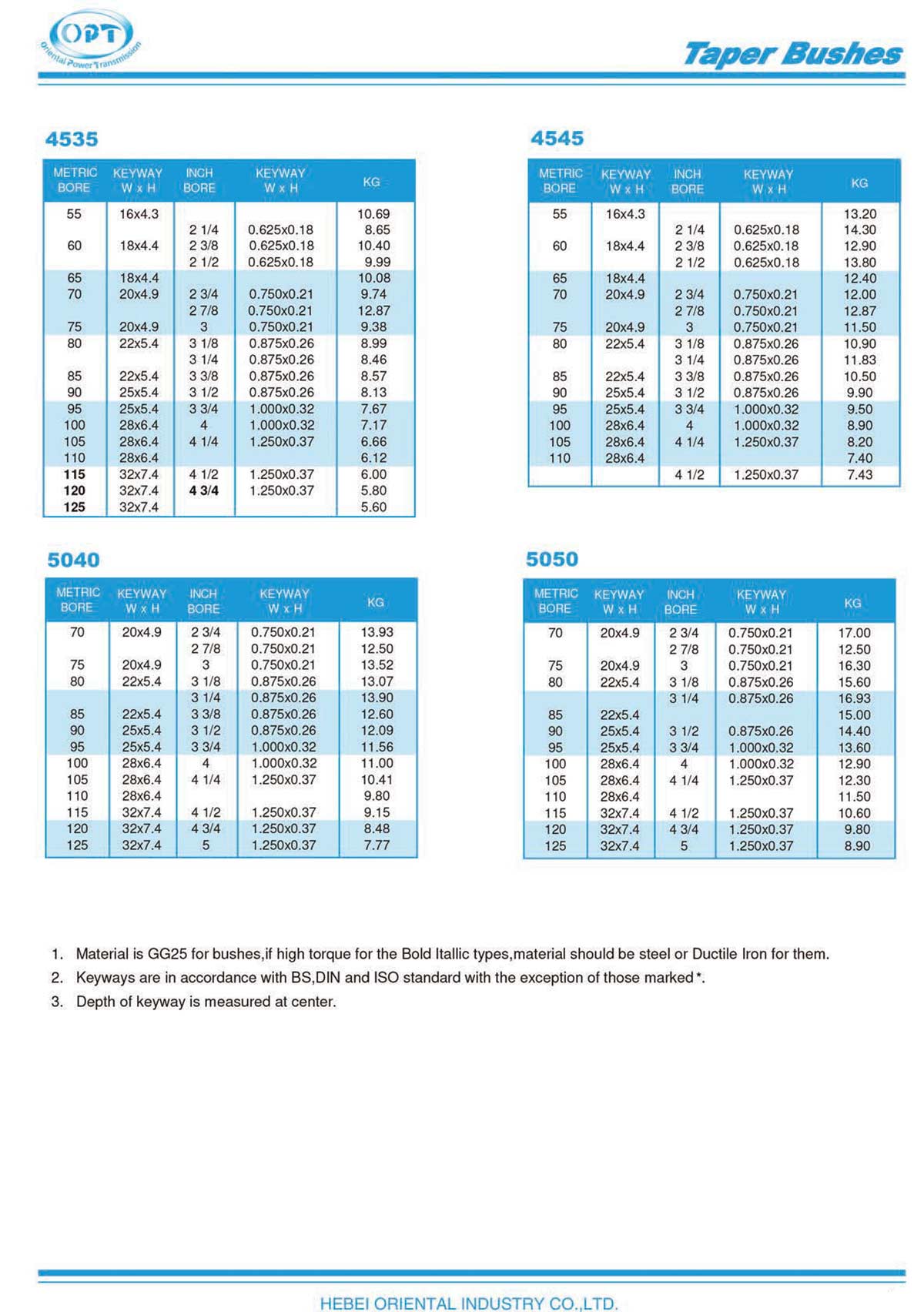

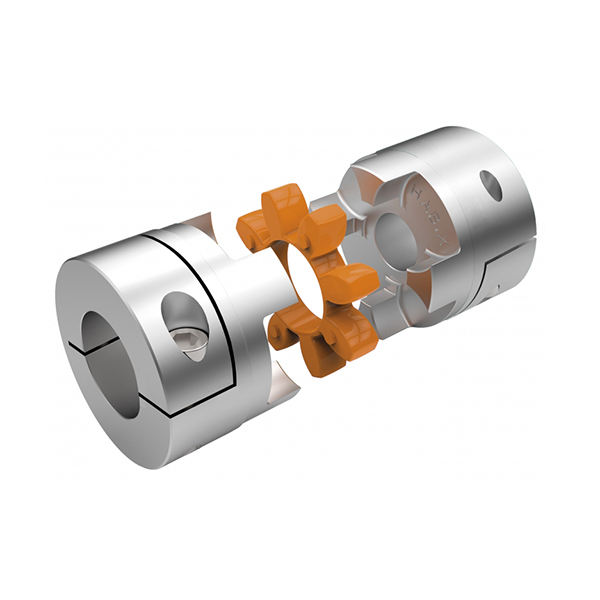

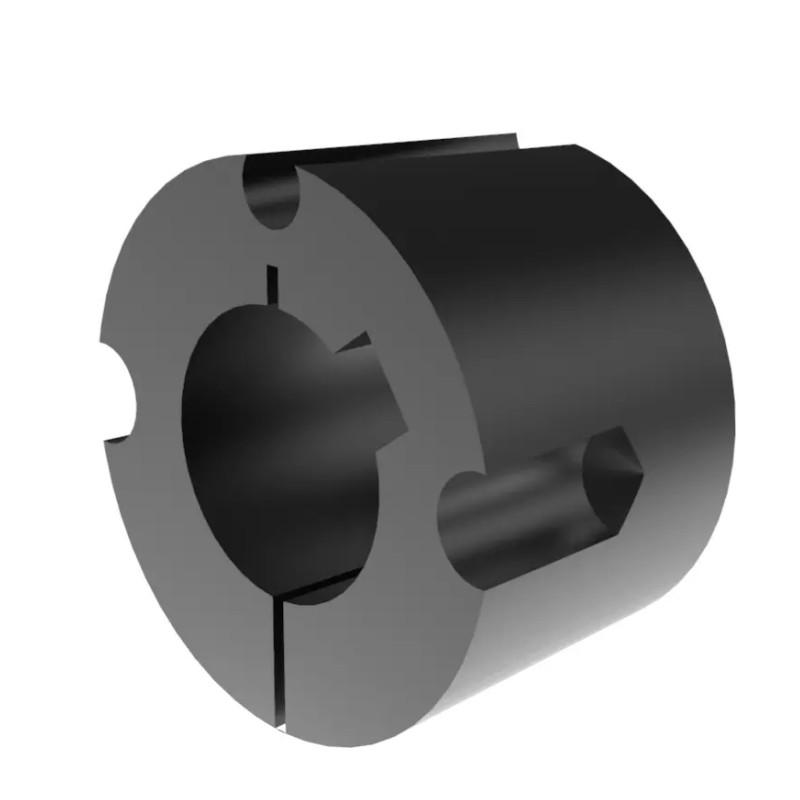

Taper bushings are mechanical parts used to mount pulleys, sprockets, or gears to shafts.

It is designed to be mounted on a shaft with a tapered bore and to be screwed or bolted.

The taper of the bushing matches the taper of the shaft, creating a strong and precise fit that can withstand high levels of torque and vibration without slipping.

Tapered bushings are commonly used in power transmission applications in various industries including mining, manufacturing and construction.Taper bushes are the most convenient and cost effective method of fixing components to a mating shaft without using any special tools.

Taper bushes are already provided with the required bore,

keyway, threaded holes and setting screws, thus allowing

to save time and money on machining processes.

All taper bushes in our range are designed for use with all the following products:

Chain sprockets

V-belt pulleys

Timing belt pulleys

Flexible couplings

HRC couplings

Weld-on hubs

INSTALLATON

(1) After ensuring that the mating surfaces are clean and free from oil and dirt, insert bush in wheel hub so that holes line up.

(2) Place screws loosely in the threaded holes. Clean shaft and fit assembly to shaft in the position desired, considering that bush will grip the shaft first and then the wheel.

(3) Tighten screws first by hand,

(4) Then using an Allen wrench, gradually and alternately. After short time running of the drive, check tightness of screws.

REMOVAL

(5) Loosen all screws and remove one or two according to the number of removal holes. Insert screws into removal holes and tighten them alternately until the bush is loosened and the assembly is free on the shaft Remove assembly from the shaft.

-

-